By Prof. Dr. Götz-Andreas Kemmner

Scheduling parameter optimization is a methodology discussed and applied in many companies today. However, consistent maintenance of the scheduling parameters is only useful if the daily scheduling largely adheres to them. With the help of target stock management, the application of an MRP system can be effectively monitored on an ongoing basis and the focus remains on the goal of high delivery capability with the lowest possible stock levels.

Optimization of scheduling parameters refers to the correct item-specific definition of planning, control and scheduling parameters and procedures as well as the ongoing readjustment of these parameter and procedure settings. To simplify matters, the term “dispensing parameter optimization” or “DPO” is often used. With the DPO, this readjustment is not done by analyzing article by article by the users and making individual adjustments to the master data according to their ideas and experience. Instead, the DPO is based on a set of disposition rules. This set of rules defines which master data settings are to be made for which article properties.

A classic and simple example is readiness to deliver. For example, an MRP rulebook could stipulate that all A articles with regular demand, so-called AX articles, should always be managed with 98% availability, while highly irregularly demanded CZ articles should only be managed with 93% availability. Because master data settings are not linked to a material number but to material properties, necessary master data changes can be read from an MRP system and these can be efficiently maintained in the ERP system with the support of suitable software tools.

The great advantage of these dispensing systems:

- Master data settings are based on objective rules and not on the subjective opinions of individual users.

- Using suitable tools, the master data settings can be simulatively optimized so that the ERP system generates the most economical scheduling proposals possible.

- A powerful dispatching control system enables even inexperienced dispatchers to carry out dispatching at a high level.

- The scheduling process can be significantly automated and carried out more efficiently.

With an optimized MRP system, however, part of the scheduling work can be automated, primarily for regular items on the one hand and for irregular C-items on the other.

In order to realize the potential of good scheduling rules in practice in the long term, a suitable controlling system is required to identify the extent to which the actual scheduling deviates from the scheduling that would result from the scheduling settings of the ERP system according to the scheduling rules in practical application. Target inventory management has proven to be an effective controlling instrument.

The idea of target inventory management points in the right direction

The core of the target stock element are target average stocks determined for specific material numbers, referred to as “target stocks” for the sake of simplicity. The target stock of an item is determined by the MRP settings of the ERP or merchandise management system according to the MRP rules.

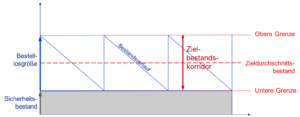

The easiest way to illustrate the target stock level is using the example of a reorder point control system (Fig. 1):

In the case of the in Fig. 1 for safety stock and order lot size results in the displayed target average stock. Of course, the stock trend does not follow the target average stock, but oscillates around it in the form of a sawtooth curve between a lower stock limit and an upper stock limit.

If an individual item is considered in target stock management, it may fluctuate between the lower stock limit and the upper stock limit. If target stock values are applied to a large quantity of materials, then following the law of large numbers, it is assumed that the stock trends below the target average stock level for some of the materials and above the target average stock level for the other part of the materials neutralize each other, so that the target stock level of a larger quantity of items corresponds to the sum of the target average stock levels of the individual items.

The reference values for target average stock, upper stock limit and lower stock limit are determined from the stock trends as they result from the typical trends of the item stock accounts.

Determining target stocks from an ideal world is wrong

However, calculating the benchmark values for target inventory management from such an ideal world falls short and leads to unrealistic reference values.

Ultimately, even the most efficient MRP rules cannot ensure that the ERP system always generates the correct MRP suggestions for all items. When calculating order or production proposals, MRP control systems and ERP systems can only be based on the information that is mapped in the ERP system.

Much of the information available to production controllers and dispatchers is not even stored in the ERP system, e.g:

- that a supplier has temporary delivery difficulties,

- an alternative supplier is currently offering particularly favorable prices,

- a system has broken down in production,

- the sales department is in negotiations with an important customer regarding a major order at short notice.

- There are ongoing shifts in demand, which may mean that an order that seemed necessary and was carried out yesterday would no longer be necessary today, etc.

This and similar types of information are rarely stored in detail and therefore cannot be taken into account when creating disposition proposals.

Experience has shown that in retail companies, around 70-80% of scheduling proposals can be adopted by users without the need to adjust quantities or dates. For manufacturing companies, the rate is likely to be around 10-20% lower.

A certain proportion of scheduling proposals, but only a certain proportion, must therefore be adapted by the users with regard to quantities, deadlines, suppliers, production facilities or similar.

Generating reference values from the future ideal stock flows according to the MRP settings of the ERP system must inevitably fail in this situation.

One such, shown in Fig. 1, which never affects the safety stock, can only be seen in practice for the future planned stock trend, as it appears when looking at the item stock accounts. Although most ERP systems do not offer this, it is still quite easy to calculate an ideal target average stock.

It becomes more difficult with the reference value of the upper stock limit. This cannot normally be represented as a simple horizontal value, even in the ideal-typical view. As Figure 2 shows, a real planning situation results in a fluctuating upper limit for the future planning stock development.

The theoretical lower stock limit, on the other hand, which is undercut in the planning future analysis at most within the replacement period, is shown in Fig. 2 also shows, from the safety stock. This lower stock limit is completely unrealistic in practice. The purpose of safety stock is precisely to absorb some of the planning uncertainties in the form of unexpected requirements, insufficient or late deliveries or scrap rates.

A safety stock is always in relation to a required level of delivery readiness. This is generally less than 100 %, which means that the safety stock is not only attacked in practice, but may occasionally even fall to zero (!). A safety stock that is never attacked is impractical; the same applies to the safety stock as the lower stock limit in target stock management.

All in all, it can be said that Traditional target inventory management forms its reference values on the basis of an ideal-typical view that never corresponds to the subsequent course of the inventory. For the reasons described above, the reference values are not very meaningful in traditional inventory management.

No matter how good the regulations are, practical stock flows deviate from the ideal stock flows. Therefore, anyone who determines reference values for item stocks from ideal-typical target stock trends is comparing the apples of the ideal world with the pears of reality. In this way, stock deviations from the “ideal line”, which are unavoidable in practice, are presented to the dispatchers.

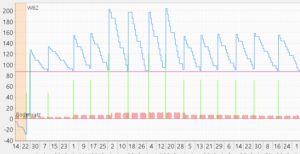

Using simulation to achieve reliable target stocks

The entire target stock management stands and falls with the calculation of the material number-specific target stocks and target stock corridors. Realistic reference values for target stock levels and stock corridors can only be determined by means of an item-specific simulation based on the specified scheduling rules. In such a simulation, the scheduling behavior of the item is simulated in accordance with the specifications of the scheduling rules over a certain period of time in the past, taking into account the actual demand situation during the historical period under consideration. In this way, it is determined how the item-specific MRP settings and parameters would have behaved in the past compared to the actual daily demand situation. Only then can a realistic target (average) stock be calculated. In this way, the ERP optimization system DISKOVER SCO from SCT GmbH, for example, simulates the target average stock levels material number by material number (Fig. 2).

The key indicator for this type of target inventory management is the target average inventory. Although a maximum and minimum stock level could also be determined from the simulation, the latter is zero in many cases. However, these two values have little control effect, as the two values may only have been reached once over the simulation period and should therefore be regarded as general limits that are too extreme.

It is more effective to derive a current and general stock reduction potential – or a corresponding need to increase stock – from the simulated target average stock in comparison with the current stock value and the actual average stock per item. The actual average stock of an item is calculated over the same time period over which the simulated average stock was determined.

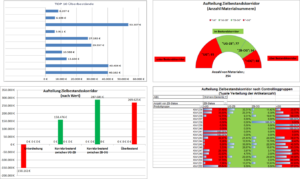

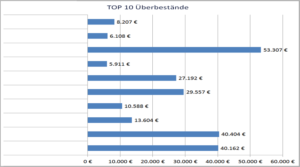

With the inventory reduction potential as a key figure, very effective inventory controlling can now be set up. The inventory reduction potential can be shown for a single item as well as for any group of items.

The addition of stocks or target stocks for a group of articles cannot usually be carried out on the basis of physical units such as pieces, tons, bags or m². It makes little sense to add five hairpins to 8 laptops; the total values must be considered in monetary units. The example of the 5 hairpins at 0.5 ct each and the 8 laptops at €560 each clearly shows that the value of an item is automatically included in the target inventory analysis. If the target average stock of 5 hairpins is exceeded by 500%, there are 5 x 2.5 ct too many in stock. If the target stock of laptops is exceeded by 12.5%, there is €560 too much in stock. Target stock deviations for expensive items have a greater impact on target stock management than deviations for low-value items, which is intentional.

For this reason, the items with the largest absolute inventory variances are of particular interest in target inventory management (see Fig. 3).

In conventional target stock management, it should be noted for the sake of completeness, not only the items with excess stock are considered, but also the “position” of the items in the target stock corridor. In this context, items with excess stocks are only those items whose stocks exceed the rather arbitrary and theoretical limit of the upper stock corridor. The same applies vice versa for items whose stocks are below the lower stock limit. With regard to the “position” in the stock corridor, a decision can be made between items that lie between the lower stock limit and the target average stock and those whose stock levels are above the target average stock but below the upper stock limit (see Fig. 4).

The supposedly more differentiated view sometimes belies the poor informative value and low resilience of this type of reference value formation.

Only with the help of simulative target stock controlling will you be able to efficiently and effectively monitor the extent to which operational scheduling and production control adhere to the specifications from the ERP system and MRP rules. Track the deviations over time, scrutinize the causes of the deviations in general and the increase in deviations in particular. This will not only improve the discipline of operational scheduling and production control, but also increase the quality of your MRP system.