By Dr. Bernd Reineke and Marina Weniger

For decades, OASE has stood for products for creative design with the medium of water. Fascinating ponds and water features in domestic gardens through to impressive large-scale installations in public areas demonstrate the wide range of applications. Founded in 1949, OASE has developed into a global player with a claim to innovation and quality leadership.

The procurement and supply structure at OASE has developed in a similar way to the sales markets. Production and procurement now span the entire globe with suppliers and service providers on all continents and production facilities in Germany and abroad.

With the help of suitable software, it should be possible to plan procurement channels and present them transparently. Furthermore, the globally distributed capacities had to be planned and bottlenecks identified and avoided. To meet these requirements, OASE opted for the DISKOVER SCO planning and optimization tool from SCT GmbH.

DISKOVER SCO comes out on top

An initial solution with a competitor’s product turned out to be too complex in terms of data provision and administration and could not ensure the required process stability due to interface problems.

In the search for a lean, easy-to-use and yet very powerful system, the choice fell on DISKOVER SCO, which convinced the OASE team with its well thought-out structure, simplicity in the administration of complex structures and powerful optimization algorithms.

Another argument in favor of DISKOVER SCO was the comprehensive range of services offered by SCT GmbH’s support team. In addition to the usual functions such as hotline support and update service, this also includes an exception guard that detects deviations from the target status of the software as well as the logistical parameters and processes and informs support and users alike via an automated notification service. The system settings are also checked and scrutinized at regular intervals and adjusted in consultation with the customer if necessary.

OASE, a demanding user

OASE was not only a great challenge from a technical point of view with the complex structures already mentioned. There were also high demands in terms of project management: the system was to go live within just four months. To this end, a project team was formed in which the sales, purchasing, scheduling, production and IT departments were represented and which always participated fully in the workshops. As a result, it was always possible to clarify and coordinate questions and unresolved issues comprehensively.

The results

As part of the project, many topics relevant to disposition were coordinated and implemented. As a result, numerous rules were defined that determine exactly which parameters are to be set in which situations. To manage the complexity of this multitude of rules, the rules are organized in topic-related decision tables. Furthermore, filters can be set for each decision table to specify the materials for which the contained rules are valid and the criteria. Below you will find an excerpt of the points implemented:

Disposition according to life cycle:

DISKOVER SCO regularly determines the life cycle indicator (ELA) of all materials according to the categories entry phase (E), life phase (L) and phase-out phase (A), whereby the phase-out phase is divided into four different stages. Depending on when the material is phased out and whether, for example, a penalty is linked to the availability of the material, the parameters can be set in such a way that the stocks of components and products are reduced to the lowest possible level at the end of the phase-out phase. Components that are still required as spare parts are also given the correct settings via the rules in DISKOVER SCO.

Optimization of forecasts and safety stocks

An important aspect of the project was the optimization of forecasts and safety stocks for finished products as well as for assemblies and components. Optimizing forecasts and safety stocks usually means that products and components should be available as required. Planners and dispatchers are overwhelmed when it comes to selecting and determining suitable forecasting and safety stock procedures. How is one supposed to determine the right one from the multitude of procedures and parameters? Even the optimization algorithms in ERP systems are often inadequate and easily produce incorrect results. This can have fatal consequences, resulting in overstocking or supply bottlenecks. The simulation-based algorithms in DISKOVER SCO are more effective in this respect. The required delivery readiness and stocks are brought into harmony. The dispatcher can rely on the results from DISKOVER SCO and can concentrate on other important tasks.

Production planning

As already mentioned, the supply chain at Oase is quite complex, as production, procurement and shipping are organized across several plants and the corresponding supply relationships between these plants had to be mapped. This can be represented in DISKOVER SCO not only technically but also visually via the supply network design. A graphic shows the user not only the BOM relationships, but also the intercompany procurement routes.

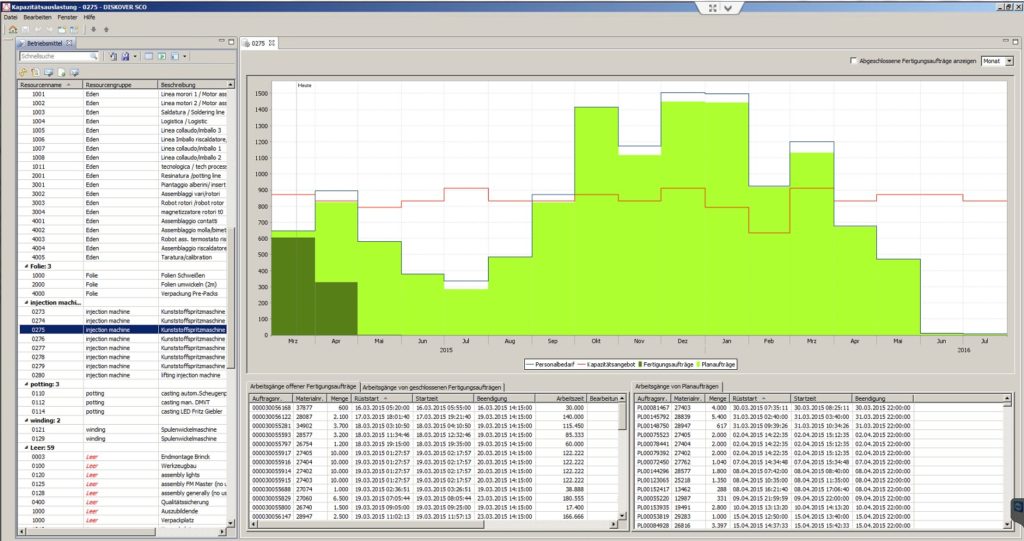

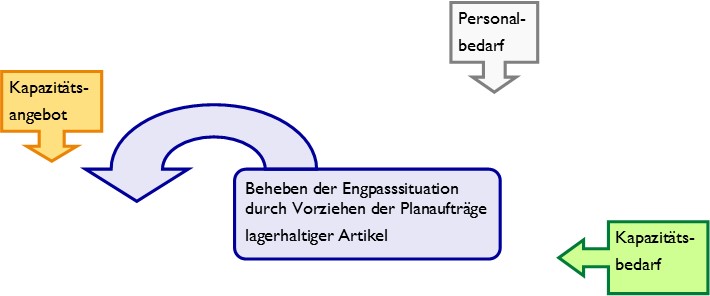

At Oase, the efficient use of available production resources is particularly important. In addition to adherence to deadlines and quantities, production controllers must also keep an eye on capacity utilization at the production sites. DISKOVER SCO helps you to do this by displaying all relevant production resources with available and current loads. In the graphical and tabular view, the planner immediately recognizes a critical situation and can initiate the necessary measures.

Anyone who, like Oase, produces and procures in an international network is familiar with the challenges posed by different vacation and public vacation regulations due to weeks-long closures of production companies and the subsequent slow start-up of production and logistics processes. Here too, DISKOVER SCO offers appropriate options for mapping production-free periods and automatically generating suggestions for the planner to initiate stockpiling in good time so that a continuous supply of components and products is guaranteed.

Interfaces

Within a few weeks, the supply network was mapped in DISKOVER SCO. To this end, master and transaction data is exchanged in a daily night run and transferred to the DISKOVER SCO structures. Forecasts and safety stocks could be optimized as soon as the consumption data was available. The greatest effort lay in developing the rules and regulations for the dispensing parameters and various stockpiling strategies. The aim here was to collect the expert knowledge in the heads of the dispatchers and controllers and to map it in the form of rules. The so-called “gut feeling” (often also referred to as experience) was also discussed and taken into account through corresponding rules. The planning and scheduling results are therefore reproducible and traceable at all times. It was not least this aspect that led to rapid acceptance of the new solution.

Today, OASE benefits from the close support provided by the employees of SCT GmbH. Questions and problems are addressed and answered by competent contact persons. This is also an important aspect in the selection of a system partner, as the high complexity of the interrelationships can only be grasped by people who are deeply familiar with the subject.

Further information on this topic can be found here:

- [intlink id=”5059″ type=”post”]Short & sweet: The ELA analysis[/intlink]

- [intlink id=”9363″ type=”post”]ASK Chemicals automates sales and demand planning[/intlink]

- [intlink id=”5715″ type=”post”]From hands-on tools to a professional solution[/intlink]