Automated scheduling minimizes portfolio risks

by Mariusz Zdanowiecki, RCS Sp.z.o.o., and Andreas Capellmann, SCT GmbH

If wholesalers want to survive in the Internet age, they have to be able to deliver more and more items in less and less time. To prevent stock levels from exploding with hundreds of thousands of items and more, only automated replenishment can reduce stock levels without compromising delivery readiness or, alternatively, causing personnel costs to skyrocket. Advanced Planning & Scheduling software such as DISKOVER SCO from SCT GmbH can help here. This is the experience of ASAJ, a wholesaler organized in FEGIME.

Today, we are used to getting even the most exotic products delivered by post in batch size 1 within 24 hours. This also has a huge impact on B2B demand in the retail and trade sectors. Wholesalers need to expand and/or deepen their product range in order to reliably meet the increasingly fragmented demand. However, storage capacities for fast delivery cannot be expanded at will, as an increasing variety of articles also ties up costs. In addition to the pure capital commitment, which ties up large amounts of liquidity that could possibly be used more effectively elsewhere, inventories account for 18 to 30 percent of inventory values in running costs per year. These are made up of capital costs, insurance, administrative expenses, obsolescence and scrapping and other cost factors. Wholesalers have to pay these costs if their logistics chain is not right. But how can you increase delivery readiness and at the same time reduce stock levels despite increasing article numbers and decreasing demand per article?

Optimize scheduling processes

First and foremost, it is a question of better scheduling processes. For example, you can order fast-moving items at shorter intervals. This reduces storage capacity. Products that are in particularly low demand are only ordered when needed and removed from stock. In most wholesale companies, it is also possible to optimize the logistical parameters. As a result, safety stocks are often only planned on instinct and adjusted ‘as required’ without generally applicable rules and regulations. Filling a pallet space in the truck with slow-moving items just to save freight costs can also drive up stock levels ‘sustainably’. So there is a lot to optimize across the entire supply chain.

Method and tool skills

Method and tool skills are required for this. One of the most important tasks is an extended ABC analysis. In other words, a classification of the complete range of articles according to

- ABC – economic significance,

- XYZ – Regularity of consumption,

- STU – number of customers per item and

- ELA – Life cycle

These classification characteristics are important parameters for deciding which planning and scheduling parameters should be set for which articles and which article classes should be planned and scheduled and how. With such basic analyses, existing stocks can be quickly reduced and delivery readiness increased at the same time. But all such analyses and the measures derived from them are not enough if dispatchers are not supported by suitable software, for example.

This was also the conclusion reached by the Polish wholesale chain ASAJ Sp. Z o.o., which operates in the field of electrical and lighting engineering and is a member of FEGIME[1] Poland. The company operates 21 stores, employs 300 staff and currently offers around 275,000 items, which are replenished daily. The number of articles alone gives an idea of how important a modern IT system is. For a long time, ASAJ relied on the expansion of its ERP system to effectively support employees in the purchasing department when creating delivery orders. Increasingly, the question arises as to whether the commitment of a single IT department is sufficient to keep up with the sophisticated solutions of special forecasting and scheduling systems available on the market and whether the know-how of further development can be maintained and expanded within the company. ASAJ realized that a massive step forward could improve competitiveness and significantly reduce the company’s running costs. ASAJ entrusted a logistics consulting specialist with the task of working out the strategic requirements of modern planning and scheduling for ASAJ, and together they defined four goals to be achieved with the use of such a software solution:

- Reduction in the amount of work involved and therefore a reduction in the costs incurred when preparing orders.

- Complete automation of the replenishment of the 21 stores from the three

- Complete automation of the stock transfer of articles with a low turnover rate.

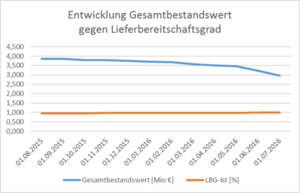

- Reduction of stock levels and simultaneous increase in delivery readiness.

For the implementation, the Polish logistics consultants recommended the Advanced Planning and Scheduling (APS) software tool DISKOVER SCO, which is produced by SCT GmbH in Herzogenrath / Aachen and is distributed and introduced in Poland by the implementation specialist RCS. Once Team SCT and RCS had been selected, ASAJ’s purchasing department drew up a detailed specification of ASAJ’s specific requirements and agreed them with RCS. DISKOVER did not have any standard interfaces to the Comarch ERP XL ERP system used by ASAJ. However, thanks to the IT department’s extensive detailed knowledge of the COMARCH system, this was quickly implemented within a month.

Straightforward introduction of the new APS software into everyday working life

The second stage in the introduction of the APS software involved user training. The on-the-job training approach, in which employees are trained by interacting directly with the new software in their day-to-day work, has proved successful and was largely completed after just three weeks.

A real challenge in implementing the APS software was choosing a time for the go-live, i.e. the complete changeover from the previous in-house ASAJ tools for forecasting and ordering to the DISKOVER system. In practice, this meant that the previously used methods and ways of thinking in terms of minimum and maximum stock levels had to be replaced by the more statistical concept of delivery readiness level and safety stock. In the end, this changeover for the entire company was completed in just one day, as the purchasing department was very well prepared for the independent operation of the APS software. To further increase the security of the project, RCS supported the users at ASAJ during the start-up phase by telephone and remote access via TeamViewer.

During the first weeks of productive operation, RCS also supported ASAJ employees in optimizing the most important scheduling parameters. Robert Dabrowski, the project manager, summarizes: “Our partner, RCS, always answered our questions promptly and provided us with constant support in setting and optimizing parameters. The complete implementation of the APS tools took just 3 months from signing the order to going live.“

All targets successfully achieved

The four goals of the APS implementation were all successfully achieved with DISKOVER and thanks to a clever and pragmatic implementation concept. “The overall aim of the implementation is to achieve maximum profit with minimum capital expenditure,” explains Kamil Kulma, Production Manager on the project steering committee. “We are approaching this goal step by step and DISKOVER SCO is helping us to increase our competitiveness and significantly boost our profits.”

[1 ] FEGIME Fédération Européenne des Grossistes Indépendants en Matériel Electrique (European Federation of Independent Electrical Wholesalers) is an association of over 160 wholesalers from nine European countries.