The acronym POLCA stands for Paired-Cell Overlapping Loopsof Cardswith Authorization and was developed in 1998 by Rajan Suri as an alternative to Kanban.

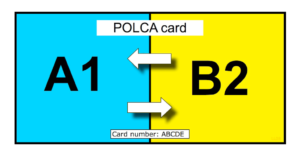

In production, the stocks of the individual production islands are controlled decentrally via POLCA cards according to the pull principle. Each card shows which unit the material comes from and which unit it should go to.

The production islands form pairs or loops between which the cards assigned to them rotate and mutually authorize order processing. Rough planning is used to determine how many cards each island has in circulation in a certain period of time:

If the start date for production has been reached or exceeded and the receiving production island B2 is ready to accept the order according to the POLCA card, the order can be processed in A1. The card is then sent to the receiving cell B2 together with the product. When this is ready for further recording, the card is returned to the A1 transmitter, which can then process another order. If the capacity of the recipient cell B2 is exhausted, the card remains with it and the upstream cell A1 can bring forward another order. If B2 has free capacity again, the card is sent back to A1 and the order is then produced there when the production deadline is reached.

The material flow thus virtually “dances” through production, avoiding long throughput times, build-up of circulating stock and idling / overloading at the individual production islands.

Our tip:

POLCA is particularly useful for high capacity utilization and articles with sporadic demand in complex production processes. For simpler production structures or series production, ConWIP offers a simpler solution to ensure a uniform flow with maximum WIP.