Supply chain optimization software with an all-round perspective

By Dipl.-Kfm. Armin Klüttgen

Who hasn’t heard the saying: “It’s in the eye of the beholder!” – and where is this more true than in customer and supplier relationships, where the parties involved agree on whether the agreed service has been fulfilled or not?

All-round perspective as a consultant and user

For more than fifteen years now, I have been a consultant who uses software in consulting projects and also acts as a supplier to customers who then use this software operationally.

On the other hand, I also managed the planning of an industrial company for several years, which had to overcome many exciting challenges in the planning environment and did so, among other things, with the operational use and support of DISKOVER, the supply chain optimization software from SCT GmbH, and still does today.

This gives me a very good all-round view of DISKOVER, namely that of the supplier or consultant and that of the customer. A very exciting, valuable and important experience that broadens your own scope of knowledge and fills it with many new and fresh aspects in the interests of the customer.

Why use supply chain optimization software?

Supply chain management (SCM) involves making planning decisions that can very quickly have a major impact on the company’s results. And if you do a lot of things right, this influence is positive. However, it can also very quickly lead to economic difficulties, e.g. in terms of budget achievement.

The DISKOVER SCO supply chain optimization software is used by consultants in optimization projects to systematically simulate value streams and to optimize planning methods and parameters in the company – and thus to improve company results. At the same time, DISKOVER is an APS tool(Advanced Planning System) that customers can rent and use for planning and scheduling in both operational and tactical/strategic operations, so that results can be sustainably improved and permanently optimized.

Large, small and new levers

The consultant is the one who uses DISKOVER in consulting projects to identify significant potential and generate recommendations for action that can leverage this potential. Very often, the consultant is expected to achieve a 10, 20 or more % reduction in stock and at the same time a noticeable increase in delivery readiness. Experience shows that these ambitious goals are often confirmed by the analyses in which the software is used intensively. However, the complexity of the underlying processes makes it impossible to make serious statements about such results without the support of a powerful simulation tool. Here, the software helps to model the improved processes and parameters and then determine or prove the achievable potential based on “figures – data – facts”.

Achieving these ambitious goals or great potentials often requires very complex and diverse changes both in processes and in the supporting systems, which is tantamount to moving a large lever with equally large effects. The customer supports this through intensive project work as part of a DISKOVER system implementation, so that DISKOVER can go live with a very well adjusted planning and scheduling system. Once the system has been introduced, DISKOVER is not only used by the customer in operational use to handle daily planning and scheduling processes, but is also used in a variety of ways to identify further potential. These are small levers that are moved, but they can always lead to significant improvements.

This is all the more true if the company’s business model undergoes a realignment or if environmental variables such as production conditions, market requirements, purchasing conditions, etc. change significantly. In such situations, the DISKOVER system with its genuine simulation options provides valuable support in adapting to the new conditions, so that the best possible planning can continue to be carried out with minimum effort and cost.

At the same time, the software offers the opportunity to generate completely new levers and implement them at short notice. During my time as planning manager and customer, we developed many dozens of ideas and conceptual approaches together with SCT GmbH, which developed DISKOVER SCO, and implemented them in the software. This has repeatedly resulted in many positive effects, as the software subsequently provides even better support for company-specific processes and requirements, thereby boosting efficiency and reducing costs.

These included, for example, implementations in the context of capacity planning and logistics (so-called trigger lists), very flexible automatic report dispatch, introduction of new planning articles (attribute-based clustering of sales articles based on the production article) and much more. The decisive factor here was above all that the close cooperation with SCT and its short response times meant that innovations were available very quickly and the additional benefits were therefore realized quickly.

80:20 and the sustainability issue

The introduction of DISKOVER does not mean that all potential has been realized in one fell swoop, or in other words, not all problems are solved overnight after go-live. As so often, the Pareto principle (80-20 rule) also applies here. The aim is to have a stable, efficient and high-performance basis with Go-Live, which already covers at least 80% of business transactions or shows the associated potential. This is often more than 80%, which is why Pareto should be seen as a minimum requirement.

In operations, it is then necessary to further refine the planning and scheduling methods used and their parameters. Many changes result from questioning planning results and comparing different attitudes with their effects. In addition, during operation, it quickly becomes clear where gaps still need to be closed in the system settings or in the coverage of the relevant business transactions. In this way, the missing 20% are then gradually developed.

This is also the phase in which the main activities are transferred from the consultant to the client. The consultant continues to provide support on many issues and, where possible, contributes further ideas, but the reins of proactive action are now increasingly passing from the consultant to the client. The role of DISKOVER users and, in particular, DISKOVER key users is becoming increasingly important here. Their activities are increasingly the key to the small and new levers that enable the full exploitation of all potential and, above all, ensure the absolutely necessary sustainability.

The planning world is highly dynamic and changeable. In order to always achieve the best possible planning results in such an environment, it is not enough for DISKOVER users to deal with the daily customer and production orders to be processed and the stock situation.

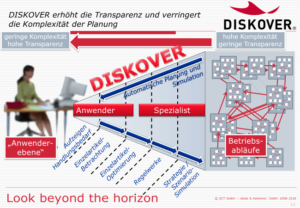

The planner’s tasks go far beyond looking at individual items from an MRP perspective(see Fig. 1). In addition to the optimization of individual items, which is largely achieved through careful maintenance and further development of the rules and regulations, the optimization of tactical and strategic alignment is also particularly important. Questions such as “is the company’s operational business model still the right one?” and, if applicable, “which operational business model has which effects and how should it be modeled in the system?” are key lines of action, especially for DISKOVER key users. In this respect, constant adjustment and proactive continuous improvement are required in terms of sustainability, which is very efficiently supported in DISKOVER by user-friendly tools, such as the possibility of simulating different scenarios and the use of automatic rule sets.

Only with this tool support was it possible to move the many different levers and achieve success in the short term.

Figure 1: DISKOVER and its different levels of action

Laboratory and real life

In the initial installation, DISKOVER covers a laboratory situation in a certain sense. The given operational business model, e.g. stock manufacturer, contract manufacturer or mixed forms and other circumstances are modeled. It is also assumed that a material-receiving stage, e.g. that of the finished products, is reliably supplied by the upstream location. By reliable we mean: The right article in the right quantity on the right date in the right quality, i.e. within the required tolerance. I would describe this as an ideal-typical, but rather unrealistic and therefore laboratory situation, which probably does not exist in reality in any company.

In “real life”, there is a wealth of framework conditions and restrictions that torpedo these requirements and make it difficult to adhere to the plan. A large proportion of these disruptive effects are uncovered by the consultant together with the customer during the implementation project and made controllable through appropriate organizational measures and parameterization in the system. In addition, once the system has been introduced, it is the customer’s permanent task to identify disruptive factors and to question how they and thus a larger part of reality can be made plannable or controllable through appropriate modeling in the system.

What could such disruptive factors be? In relation to the points mentioned above, these are, for example:

- Correct article:

- For a variety of reasons, the production department decides to produce another item that should actually be produced at a later date.

- In my day-to-day work, for example, it could happen that an article had to be cut shorter or narrower due to errors in the edge area, resulting in a completely unspecified article. This is then the first choice in terms of quality, but not the required item.

- Prioritization and quick fixes lead to displacement and thus to short-term changes in the product mix to be manufactured.

- correct quantity:

- A customer order that is actually supplied with the desired quantity is deprived of material by a sudden demand that occurs more quickly.

- Unstable production processes lead to strongly fluctuating output quantities and shortfalls in demand coverage.

- Demand and inventory planning is not optimized, e.g. with regard to exception planning (promotions, etc.), insufficiently defined target delivery readiness levels for stocked items, suboptimal replenishment strategies in the supply network, etc.

- Input material fails and this reduces the output quantity.

- Uncoordinated batch sizes between the different production stages lead to undersupply at a downstream stage.

- correct date:

- Malfunctions on production machines delay timely production.

- Master data in the system, e.g. set-up times and throughput times, are not properly maintained.

- Machine capacity pools are not composed correctly because, for example, they consist of machines that are not interchangeable. This makes the fluctuating product mix the determining factor.

- Fire-fighting at short notice leads to constant and massive schedule changes.

- Capacity bottlenecks make prioritization necessary, which leads to postponements.

- Insufficient personnel capacity generates delays.

- required quality:

- Errors occur that lead to total failure of the material. Material must be booked as second choice after inspection and therefore no longer meets the requirements set by the customer with regard to tolerated deviations.

- Errors have to be rectified by reworking, which consumes additional capacity.

- Production processes and technical feasibility are not optimally designed to meet the required quality tolerances.

But how can DISKOVER help the customer here? The answer to this is three aspects that DISKOVER brings into the company as a permanent process:

- Creating transparency and identifying problems and disruptive factors

- Development of concepts and strategies to control or eliminate these disruptive factors and thereby improve planning results, including the assessment of the impact on costs and benefits and thus on the company’s earnings

- Functionalities for implementing the designed concepts and strategies and thus for efficient, low-effort and best possible planning and control in “real life”.

DISKOVER offers a wealth of key figures and classifications that enable the monitoring of a wide range of planning and logistics processes and targets. In addition, it offers a very powerful reporting and pivot functionality that is extremely flexible to use and, in combination with various alarm signals, visualizes problems automatically and always up-to-date. Comprehensive transparency is the key to root cause analysis, identifying potential for improvement and designing control concepts.

Thanks to the transparency, it is now possible to decide how to deal with the identified vulnerabilities. On the one hand, these can be organizational measures that have no direct influence on the use of the system, e.g. changing a process in production or defining a clear process for producing and maintaining the best possible master data quality, without which good planning results are not feasible.

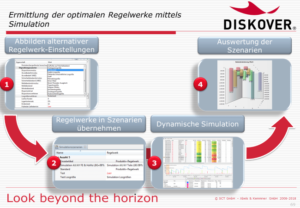

On the other hand, these are very often also changes in the planning strategy and methodology supported by DISKOVER. It is extremely important to have sufficiently checked and tested changes and realignments in this environment, which suggests verification in a realistic and therefore productive environment. To avoid exposing the company to unnecessary risks, DISKOVER offers the option of value stream simulation in the computer, similar to crash simulation in the computer in the automotive industry(see Fig. 2). Concepts, methods and their parameters can be varied with all their adjusting screws and the effects of these variations can be simulated and assessed and evaluated in all their consequences. The prime example here is, for example, the question of what inventory costs are incurred if you set which items as being in stock and then assign them to which target delivery readiness depending on their consumption characteristics. And how many production orders would this create in terms of production capacity requirements or how many deliveries would logistics have to handle?

Figure 2: Simulations determine the optimal set of rules

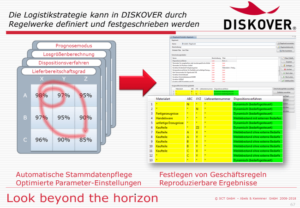

If conceptual changes need to be implemented in planning and scheduling on the system side, DISKOVER helps in particular through the automated use of rule sets(see Fig. 3). The set of rules defines how which article or other business objects, e.g. storage locations, customers, suppliers, orders, etc. are to be set up and handled. The decisive factor here is that people think about these rules and formulate them on the basis of the findings from the simulation. This leads to an immense gain in efficiency, as the set of rules then automatically makes all settings every night according to the rules. This ensures that all articles and other business objects are optimally set at all times and that the settings are always traceable and reproducible. At the same time, it reduces the planning effort and creates the necessary space to think about further planning improvements.

Figure 3: Regulations implement the desired strategies

And in this phase, the implementation of the best possible planning, the simulation again provides valuable assistance. What planner has the time to check the optimum combination of forecast and safety stock procedures with all the relevant parameters for all their items on a rolling monthly basis and to readjust them if necessary? The simulation also does this job automatically and regularly, so that all items are optimally set at all times in conjunction with the set of rules.

Results log of the 360-degree inspection

In the DISKOVER application, there is a smooth transition from the consultant to the customer. Both the consultant and the customer benefit in the various phases and forms of the DISKOVER application from the opportunities provided by the system to identify potential and opportunities for improvement and to achieve set goals. DISKOVER thus helps both the consultant through project support and the customer through continuous improvements that have a lasting positive impact on the company’s results.

At the same time, DISKOVER is also subject to a continuous improvement process in very close cooperation with the customer. The world keeps turning and an APS tool has to keep evolving.