Advanced Planning & Scheduling at Leuze electronic

by Michael Schüler, Leuze electronic, and Bernd Reineke

Leuze electronic no longer optimizes its purchasing and production decision bases in the ERP system as in the past, but on the basis of the Advanced Planning & Scheduling (APS) tool DISKOVER from SCT. This delivers significantly more precise sales forecast results. Leuze electronic is not only impressed by the sophisticated sets of rules and scheduling algorithms – daily work with the tool is also very practical and therefore extremely convenient. Its introduction was accompanied by the management consultancy Abels & Kemmner.

For over 50 years, Leuze electronic has been an expert and manufacturer of measuring and switching sensors, solutions for image processing and data transmission as well as components and systems for occupational safety. Today, the company operates globally and offers its customers an extensive sales and service network. Over 1200 Sensor People work in development, production, sales and service at 24 locations worldwide, supported by more than 40 sales partners worldwide. Leuze electronic achieved record sales of 214 million euros in 2018.

Interlocking inventory and delivery reliability in planning

In order to further optimize the company’s high delivery readiness without tying up too much capital in inventories, Leuze electronic was looking for a way to present the inventory development in relation to the required delivery reliability more transparently than before. This is the only way to make well-founded decisions on adjusting the level of delivery readiness, including on the basis of capital commitment decisions. This is essential for sound corporate planning. In this way, inventories can also be viewed from a company-wide perspective by specifying corresponding KPIs and are therefore easier to manage.

This was not sufficiently possible with the ERP system previously in use. The forecasting methods provided were designed to be comparatively simple. It was possible to determine the current delivery readiness level and to control it to at least 95%, for example. However, it has never been possible to transparently show which materials and in what quantities need to be kept in stock.

Parallel introduction of the ERP and APS systems

The aim was to bring the two key performance indicators ‘stock level’ and ‘degree of readiness to deliver’ into a much better relationship than in the past and to manage them transparently and comprehensibly. With its decision to switch to SAP at its company headquarters, Leuze electronic could also have used the SAP planning tool. However, as it was more expensive and they were firmly convinced that APS tools are generally more precisely tailored to their needs, they opted for the DISKOVER tool from SCT. This proved to be ideally suited to precisely correlating the two KPIs and simulating different scenarios on the basis of numerous forecasting and safety stock procedures. As a rule, this leads to decreasing inventories while maintaining or even increasing delivery readiness.

Once the decision for both ERP and APS systems had been made, Leuze electronic introduced both solutions in parallel at its headquarters in Owen. “However, the introduction of DISKOVER SCO was much easier than the ERP introduction,” explains Michael Schüler, Head of Supply Chain Management at Leuze electronic. Firstly, because the APS system only has to map a sub-function of the entire operational process. Secondly, due to the high flexibility of the DISKOVER development team, which always reacted quickly and agilely to the requirements of Leuze electronic as part of the implementation project. “The implementation project was completed in time for the SAP system to go live. This was due not least to the high level of qualification of the implementation team and the good advice from Abels & Kemmner,” says Schüler. Both systems went live in parallel on August 1, 2018. Around six months later, the introduction of SAP was largely complete. The company is now in a position to start determining the potential for further portfolio optimization. To this end, the way in which the potential is shown in the APS system was adapted precisely to the needs of Leuze electronic.

Inter-company functions across locations

The cross-plant “inter-company” planning functions of the new APS tool are of particular benefit to Leuze electronic. Leuze electronic uses these for photoelectric sensors, barcode readers and other devices that are purchased from Leuze assembly, a Leuze subsidiary in Unterstadion near Ehingen. Transparent data exchange can be organized between different ERP systems that want to seamlessly synchronize their scheduling processes using DISKOVER as if everything were a single factory. The prerequisite for this is the flexible support of ERP systems of various designs. The APS system at Leuze also demonstrates this flexibility and integration capability, as InforLN continues to be used at the Unterstadion site.

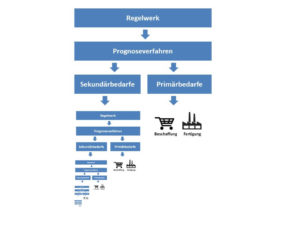

In all companies today, planning is consistently based on the unit quantity forecast of products sold in the future as the top level (primary requirements). Based on parts lists, these trigger secondary requirements for housing parts or connectors, for example. As the DISKOVER tool is also used at Leuze assembly, these forecasts can now be seamlessly transferred from the parent company and broken down to all individual parts to be manufactured. These are planned independently in the same planning run – i.e. decoupled from the end product, so that the optimum decision can be made for each part individually. The production sites or distribution hubs virtually linked to a factory via these “inter-company” functions of the APS tool therefore do not have to have the same ERP structure. Cross-plant scheduling management for purchasing and production is possible thanks to the parallel operation of the APS tool.

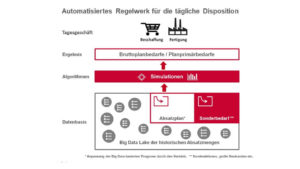

In the future, S&OP planning can also be switched to the budget and sales planning module integrated in the APS system, with sales staff editing the data directly in the APS tool screen and thus automatically adding their sales planning to the forecasts. The extent to which this data is transferred to the APS system is decided freely by each company or the decision-makers involved in this process. If the sales forecast for larger customers changes more than automatically predicted during the year, this data can also be entered in the APS tool via additional special requirements planning. This practical function was implemented especially for specific promotions, new listings or other major changes in customer relationships.

Depending on how the interaction between the sales forecast, plan and special requirements is set up in the APS system, the tool plans anew every day – including the new orders entered in the ERP system, any adjusted master data and parameters. During the initial comparison of the 2019 sales planning on the sales side, which was still implemented in the traditional way at the end of 2018, with the automatic forecast of the Operations team, the correlation between DISKOVER’s forecast and the sales planning on the sales side was clearly recognizable. There were only minimal deviations right from the start. The algorithms stored in the APS system are very good at automatically recognizing how sales trends are likely to develop in the future based on the historically collected “big data”.

Management by exception

From a planning perspective, it will only be necessary to take a closer look at these exceptional cases in future, both in sales and in scheduling. For example, by triggering the sales department via automatically sent monthly reports to report special features using the special planning options. This would allow the entire company organization to react flexibly to changes in sales. By concentrating on these few exceptions, the overall planning effort for reconciling sales sales planning with scheduling can be significantly reduced.

In the nightly MRP(Material Requirements Planning) run, the APS system determines order and production proposals – new and fully automated every day – taking into account the customer’s requested quantities and deadlines as well as stocking times and minimum order quantities. Production planners and purchasing planners then compare this with their proposal lists, which lie within the current planning horizon. If the order and/or production requirement – which has already been checked for material and machine availability in the APS system – appears plausible, it is ‘fixed’ as a ToDo in the APS system. This means it can be transferred to the ERP system at the click of a mouse. From then on, the document is managed again in the ERP system as a purchase or production order.

Ideal support for a wide range of operational processes

If the sales specifications can only be submitted at product group level, the APS tool can convert them to the individual products of the respective group on the basis of percentage distributions. This means that each individual component of each product can be recalculated on the basis of the parts lists stored in each case. This makes it much easier to plan new sales channels, as the sales distributions achieved to date within a group can also be applied to the new sales channel – sometimes with adjustments. “The solution-oriented features of DISKOVER SCO clearly show that the APS tool was developed on the basis of practical experience,” explains Schüler.

Powerful rule sets and comprehensive simulation functions

An important reason for using the new APS system lies above all in the comprehensive simulation functions, powerful rule sets, article classification options and automated parameter maintenance. All these functions enable companies to plan each component precisely down to the last detail without great effort, so that stocks can no longer be planned according to gut feeling, but on the basis of reliable facts, separated into primary and secondary requirements. In the set of rules of the tool used, it is possible, among other things, to link desired covering times with minimum quantities to be produced, which automatically optimizes the efficiency of production. However, the prerequisite for an accurate forecast and optimized scheduling is that the master data and scheduling parameters are all entered correctly in the system. Their verification by expert logistical decoupling point analyses or warehousing strategies according to ABC/XYZ analyses are essential and an important prerequisite for a successful APS introduction.

“As a result, thanks to the comprehensive rules and simulation functions of DISKOVER SCO, we now have a much more accurate forecast as a basis for scheduling and can evaluate exactly how stocks would change with changing delivery readiness levels. This is done in a standardized process with the same tools across all locations and independent of the ERP systems used,” concludes Schüler. The operational effort was also reduced by using automated trigger functions for specific tasks, such as the request to report special requirements or the regular checking of expensive minimum stock levels. By building up a comprehensive archive of key figures, the most important logistics key figures can be regularly handed over to management using standardized calculation methods. If there are deviations from the target corridor, these can be sent on an event-driven basis. This makes the controlling of scheduling management much easier.

“Based on these key figures, we can already see that Leuze electronic has been able to sustainably reduce its inventories by around 14 percent while maintaining the same level of delivery readiness. And this is based solely on more transparent information, more precise parameter settings and more differentiated warehousing strategies,” calculates Dr. Bernd Reineke, Managing Partner at Abels & Kemmner. He actively supported the introduction of the APS tool at Leuze electronic and will also uncover and implement further sustainable inventory reduction potential in follow-up projects. “We assume that we will be able to reduce the stock by a further 10 percent through various other measures.”

Also simplifies the planning of new logistics hubs

In the future, there are plans to set up a logistics hub in Singapore, from which the Asian region will be even better supplied and which will also use the new APS tool for its scheduling. Based on the history of DISKOVER, the new logistics hub can be optimally stocked right from the start, as the rules for suitable minimum stock levels can be adopted almost automatically. As a result, APS tools can also very easily provide all the decision-making bases needed to set up or dismantle distributed distribution locations and warehouses.