AI in detailed production planning? Digitization is not an end in itself. There must be a benefit behind it. There is always potential when processes can be automated through the use of digital technology, i.e. when manual and cognitive activities can be replaced. As a result, these processes are not only faster and less time-consuming, but also achieve significantly better quality results. This can at least be said for detailed production planning.

Status Quo

Looking at large and medium-sized companies, digitalization has already found its way into almost all areas. However, the degree of digitalization varies greatly, meaning that in some areas processes are largely digital and therefore automated (e.g. finance and controlling), while in other areas there is still a very high proportion of manual activities (e.g. production, purchasing, scheduling).

Smart algorithms with AI automate detailed production planning

In practice, production planning and in particular detailed production planning are only supported to a limited extent by digital technology and AI. Although there are numerous systems that can provide support here, their use often fails because the systems themselves are so complex and therefore not transparent that they can hardly be operated by a human being. We often hear the response from planners and production controllers that the results are not comprehensible, not optimal or even wrong. “I’d better do it myself” – i.e. manually, they say.

On the other hand, even these complex systems are still unable to adequately map the complexity of production today. In production operations, for example, there are numerous restrictions such as personnel, material or tool availability, which can quickly render some planning obsolete. Furthermore, the degrees of freedom of planning, such as alternative resources and materials, must also be mapped. If you now want to map a sequence planning with consideration of all restrictions and degrees of freedom, this results in a solution space that is no longer controllable by human judgment. The multitude of possible solutions cannot simply be calculated ‘just like that’, as there is still not enough computing power available in a reasonable amount of time.

Hill climbing algorithms are used to search for local optima

The solution with AI for detailed production planning

To escape this dilemma, detailed planning tools must be based on smart algorithms. With such AI-supported detailed production planning, considerable improvements can be achieved in terms of both the management of restrictions and degrees of freedom. The power of AI is to very quickly reduce the almost endless solution space to comparatively few possible planning options. Only minor changes are made iteratively to the current solution variant until there is no further improvement. A significantly different solution variant is then selected in order to determine a local optimum again.

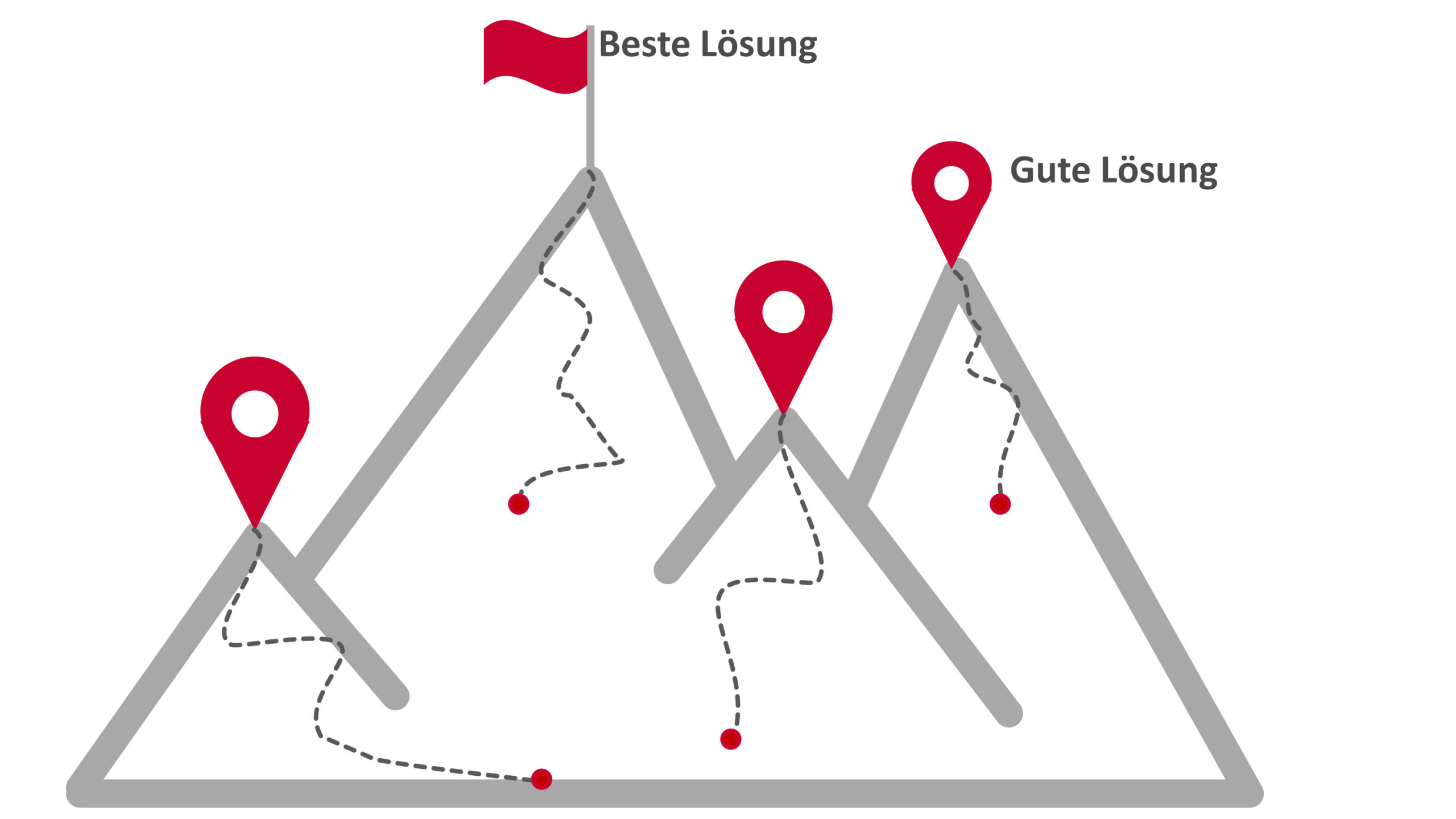

A so-called hill climbing algorithm is used for this purpose. This heuristic optimization process finds its analogy in the mountain climber who steers his steps as steeply uphill as possible. If it only goes downwards in all directions, it has reached a summit. Each individual peak is evaluated in terms of its quality and, if it is higher and therefore better than the best solution up to that point, it is adopted as the optimum. It is particularly important to define the right evaluation criteria for the solutions and to map them using algorithms in the form of score functions. Each solution examined is therefore evaluated on the basis of selected criteria such as adherence to deadlines and productivity and either adopted or rejected.

Such an AI-supported optimization run can be ideally positioned behind a classic MRP run, as offered by any conventional ERP system. In such MRP runs, availability is generally not checked, i.e. scheduling is purely demand-oriented – regardless of whether the machine, tool or material is available at the time or not. For the AI-based optimization run, this means that the sequences cannot be determined solely on the basis of the available machine capacity. Instead, the available materials, tools and resources must be dynamically allocated and released.

In the event of a material bottleneck, for example, the dispatcher would split the available material across several orders if necessary so that several customers can be supplied with initial quantities. This mechanism also represents a degree of freedom that modern detailed planning tools should automatically take into account today. The AI system should therefore be able to decide independently whether and when materials need to be divided up and orders split. Despite massively expanded functionality compared to conventional PP/DS tools, further limits of automation can already be recognized here, because no one can blame a production controller for being human if one customer is preferred to another purely emotionally.

However, it makes a lot of sense to align the handling of the degrees of freedom with the overall optimum and to fully automate this process, as this achieves better results in less time, so that you can concentrate precisely on those special rules that cannot be automated. And this is precisely the point at which you move from theory to practice.

Effects on productivity, set-up times and adherence to delivery dates

Increasing productivity through the use of AI

Set-up times are sustainably reduced

Adherence to deadlines can be significantly increased with AI

From theory to practice

Nothing is as certain as a disruption in production operations. Materials can have quality problems, machines can break down or staff can fall ill at short notice. Even an AI system cannot plan this exactly in advance. However, if disruptions occur, it is necessary to react and improvise on the store floor in order to keep costs as low as possible. In the second step, however, the disturbance variables should be made known to the AI system as quickly as possible – for example by scheduling a machine repair and adjusting material and personnel availability – and a new optimization run should be started. A short time later, there is an optimized sequence plan for the entire production area. It therefore takes a certain amount of practice to integrate the AI detailed planning tool into the daily work routine.

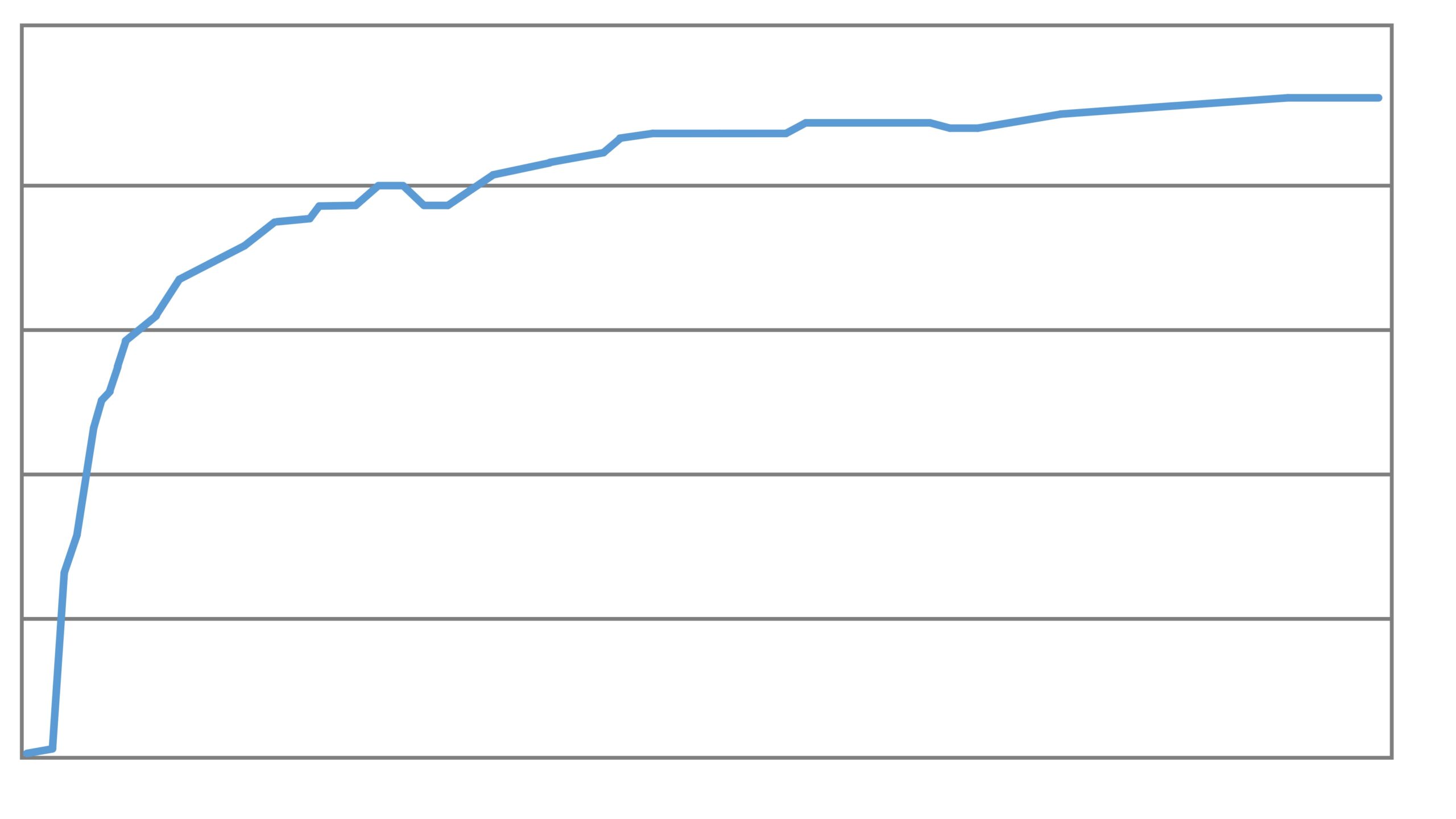

This requirement makes it clear that the demand for AI-supported detailed production planning to be implemented in practice is quite high in order to achieve the acceptance of production controllers – especially since the results can no longer be traced in detail. However, they can be easily assessed using score functions. So if deadlines are met and productivity is satisfactory, nothing stands in the way of introducing AI-based detailed production planning. If daily practice then shows that the results can be applied successfully, confidence in the solution increases constantly.

After a pilot phase, it will no longer be necessary to review the detailed planning results. At least this is the initial experience with the introduction of the new AI-based detailed planning module DISKOVER SCO DS from SCT GmbH, which is currently being implemented at the first customers. The installation is similar to a supervisor: the results of the new detailed planning, which is based on the data from the MRP run, are mirrored back to the ERP system every morning and sent from there to the workstations for production control.

The specialists on the store floor and the production controllers are delighted with the significantly better planning quality compared to conventional PP/DS systems. The production process is now much smoother, which reduces the workload on the store floor. The production controllers also have significantly more time to eliminate and prevent faults thanks to the excellent support provided by the system.

Outlook on AI in detailed production planning

As the cost of introducing and operating such a system is very quickly amortized by the immense benefits, AI-based detailed planning systems are expected to quickly gain market significance and disruptively displace conventional PP/DS systems from the market. Incidentally, their use is not only suitable for large manufacturers, but also for medium-sized companies in particular.