At Hama, predictability has priority in future!

Not so long ago, we reported on how Hama optimizes its planning with flexible standards with the help of DISKOVER SCO. As a result, the company is able to respond flexibly and react quickly to the current increase in planning dynamics. Hama has now consistently taken the next step and implemented a goods security concept that raises the delivery capability for Hama customers to a new level.

Looking ahead is taking shape

Hama GmbH & Co KG, based in Monheim, Bavaria, is one of the leading accessory specialists and sells around 18,000 products in the fields of consumer electronics, computers, telecommunications, photo/video and electrical household appliances. Hama’s product range also includes other own and partner brands.

1500 of the international company’s 2500 employees worldwide deliver up to 10,000 parcels a day from its own logistics center at its headquarters in Monheim to customers.

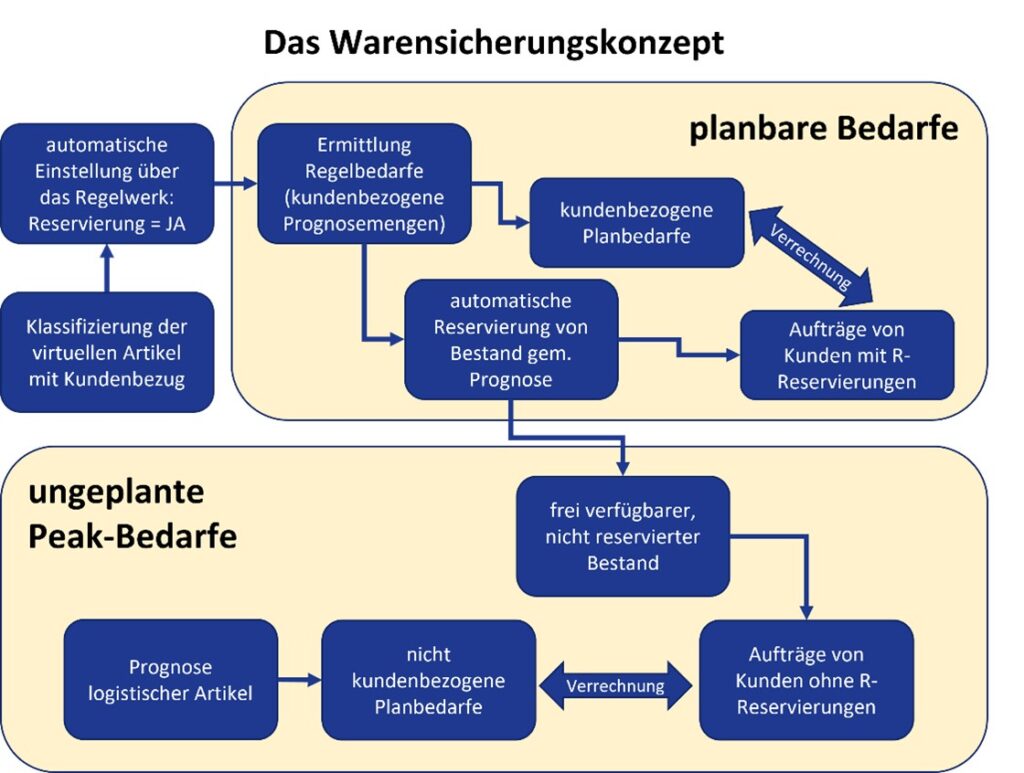

The next optimization step was to maximize the availability of goods while minimizing delivery times and stock levels. A new merchandise security concept was designed and introduced accordingly.

What has happened so far

With the introduction of the new DISKOVER SCO planning system, Hama has succeeded in supporting the requirements of the Hama business model and the Hama processes with a perfect fit. On the one hand, this ensured the desired delivery readiness while at the same time optimizing the necessary inventories. On the other hand, we succeeded in further improving the efficiency and transparency of planning and increasing planning reliability and quality. Especially now, in times of Corona, the increase in transparency has also helped to monitor and control the diverse material flows with sometimes long replenishment times and fluctuating delivery readiness of suppliers in the best possible way. The same applies to the highly volatile purchasing behavior of Hama customers.

At the same time, Hama is also constantly striving to identify further opportunities for improvement and to make these available on the system side where necessary. And in line with this guiding principle, Hama has now launched a process that opens up further potential in terms of delivery readiness and delivery reliability to the customer. The new process is mapped end-to-end in the DISKOVER SCO planning system and is in operation. In practice, it has been shown that the SCM targets mentioned above have been significantly improved.

The safety belt – the consistent implementation of the article surveillance concept

When considering how to briefly explain the new merchandise security concept, the idea of the safety belt was born. When driving a car, the seat belt has the task of protecting your physical integrity in the event of an accident, i.e. an unplanned, unforeseeable and extraordinary event.

If you convert this a little, you get a good initial picture of what the article surveillance concept can do:

The aim of implementing goods security is to be able to transport as many deliveries as possible to the customer on time and in the shortest possible time in highly-loaded SCM processes. The motto here is: Plannable requirements have priority over unplanned special departures, so that plannable requirements of Hama customers are provided with a safety belt so that an unplanned peak in the customer order cannot take away any stock from the well-planned requirements.

To this end, the DISKOVER SCO planning system automatically generates so-called standard consumption reservations which, like a safety belt, secure the goods for customers against being tapped by unplanned peak demand. The unplanned special quantities can be used from the free stock remaining after the standard consumption reservations.

As a result, the article surveillance concept ensures the basic supply of an article to all customers who purchase it.

The implementation of the seat belt

The planning process is described in the standard – very roughly – as follows:

- Forecasts are created that can be modified and refined in a variety of ways, both automatically using various set procedures and manually.

- The final forecast, the adjusted forecast, is automatically converted into planned requirements for scheduling, where they become effective as requirements such as sales orders. How the monthly forecast is broken down into individual planned requirement partial quantities with exact daily dates is determined by the planned value distribution procedure that has been set. Planned requirements can be distributed proportionally across all working days of the week, for example, or evenly across the assembly of the month or …

- In MRP, planned requirements trigger an order proposal or a planned order if the stock is insufficient, so that there is sufficient cover for the requirement.

- If a real sales order is placed, the planned requirement quantities are offset against the sales order quantities in predefined horizons and according to predefined rules so that there are no duplicate requirements.

Hama has expanded this end-to-end planning and scheduling process to include the article surveillance concept.

Maximum security of supply for predictable requirements of all customers

The aim of the article surveillance concept is to determine the quantities required for the so-called standard requirements of the articles within DISKOVER SCO and to automatically reserve these in the inventory, thereby protecting them. These requirements of Hama customers are therefore given “priority” in terms of available stock by holding “block quantities” for them.

The articles are given their own “virtual” planning article in the Sales Forecast module. This article is defined by the combination of the attributes plant number, article and customer.

For each of these virtual planning articles, DISKOVER SCO is configured via the automated rule sets to make automated R reservations (“R” stands for rule consumption).

Customer-related statistical forecast quantities for the next three months (M; M+1; M+2) are automatically reserved for the articles that are to receive standard consumption reservations according to the article classifications carried out.

At the same time, the forecast view of the “logistical article” (main article, without customer reference) in DISKOVER SCO displays the totals of the statistical customer forecasts per month in a separate line. The difference between the forecast of the logistical item and the statistical customer forecasts results in the general forecast quantity.

The two-track nature of this forecast calculation now continues in the planning. This is where planned requirements from the forecast are offset against fixed requirements elements, i.e. sales orders. In the new process, there are now regular planned requirements without customer reference and those with customer reference, depending on which of the two forecasts they originate from. A new offsetting mode set by the rules ensures that for customers with R reservations, only their orders can be offset against the planned requirements belonging to them. Customer orders that are not matched by an R reservation, i.e. customer orders with unplanned special quantities, are offset exclusively against the regular planned requirements from the general forecast.

In addition, they can only use the remaining free stock after the R reservations.

The bottom line

The Hama goods security concept ensures a high level of supply capability for the basic supply of Hama customers. So-called standard consumption reservations created automatically by DISKOVER SCO largely replace the reservations that were previously set manually. As a result, the quality of planning was further improved while at the same time having a positive effect on delivery readiness.