Material efficiency

At around 45%, material costs represent by far the largest cost block in the manufacturing industry, ahead of personnel costs (18.7%). Reason enough to constantly look for ways to reduce material costs by using materials more efficiently! A properly designed value chain and clean logistical processes can make a significant contribution to material efficiency, for example by reducing waste, lowering inventory levels, improving composite planning, reducing wear and tear and lowering scrap rates.

Looking at things from the perspective of material efficiency also reveals completely new possibilities for increasing efficiency along the entire value chain.

1% lower material costs increase the return on sales by 0.5%.

Using constraint analyses, we systematically reveal potential for improving material efficiency, identify the main starting points for improving material efficiency and develop tailor-made measures.

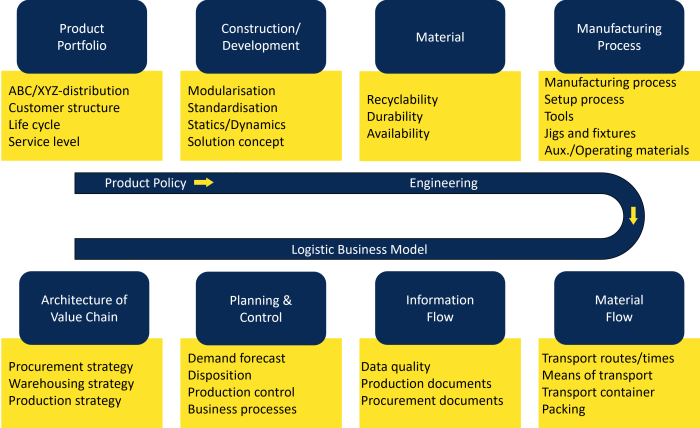

Diverse starting points for improving material efficiency

As supply chain experts, we see our individual services as building blocks that need to fit into the "big picture" in order to achieve the goal of an optimised supply chain.

Prof. Dr. Andreas Kemmner