Optimizing the logistics business model

Around 75% of the value-added costs that can be influenced depend on a company’s logistics business model. It is therefore the most important factor in a company’s competitiveness. But how can this be improved?

Every company has a (hopefully carefully considered) business model. This “corporate business model” is about the questions of what value proposition you want to give your customers, to what extent the company wants to control the value chain itself and how you want to earn money. However, this only defines the body of the company. A suitable engine in the form of a logistics business model is also required to turn this into a complete vehicle that can move around the market efficiently.

However, while the corporate business model is carefully considered, the logistics business model has usually “grown organically”. The task and goal of the logistics business model is to achieve the performance requirements resulting from the corporate business model in terms of logistics targets, such as adherence to delivery dates, readiness to deliver, delivery time, etc., while at the same time keeping the total costs of the value chain as low as possible under the given requirements. These two goals are rarely achieved optimally: sometimes the logistics business model fulfills the necessary performance requirements, but fails to keep the value creation costs sufficiently low. Just as often, we also encounter the opposite situation: the value creation costs are satisfactorily low, but the logistics performance requirements are not met. Here too, the logistics business model needs to be worked on in order to meet the performance requirements. If the logistical performance requirements can be improved, then the costs of the value chain usually increase; sometimes even beyond what is economically justifiable. And so it can happen that it is not possible to construct and adjust a logistics business model that makes it possible to implement the corporate business model. In this way, however, a USP (Unique Selling Proposition) becomes an interchangeable service.

And that brings us back to the heart of corporate strategy! Not only in such cases, but generally in order to improve earnings, it may therefore be necessary or advantageous to align the corporate business model with the possibilities of the logistics business model or to ideally harmonize the two.

The strategic importance of this logistics business model is made clear time and again by analysis results from various Abels & Kemmner projects: around 75% of the controllable value creation costs do not depend on the corporate business model, but on the correctly constructed and correctly adjusted logistics business model! This fact should make it clear how important it is to optimize the logistics business model.

The logistics business model must be structured in three dimensions:

- Firstly, through suitable logistical structuring of the product portfolio;

- secondly, through a suitable value chain architecture;

- thirdly, through the correct logistical positioning of the value chain.

Let’s take a closer look at these three dimensions:

The logistical structuring of the product portfolio can be achieved through the following measures, among others:

- Change in the shelf life of products

- Change in the ability to deliver products

- Change in the price level of products

- Product streamlining

The essential design elements from which the architecture of the value chain from the customers, through the company to the suppliers can be composed are

- the coordination of market synchronization

- the adjustment of the logistical decoupling points

- the development of postponed manufacturing

- the production segmentation

- Determining the correct degree of smoothing of the value stream

- the coordination of order-neutral and order-related production

- the optimization of storage levels

- the optimization of vertical integration

Once the architecture of the value chain is in place and the product portfolio is known, it is time to move on. to position the value chain logistically in such a way that the logistical requirements are met as far as possible and the overall costs are kept as low as possible.

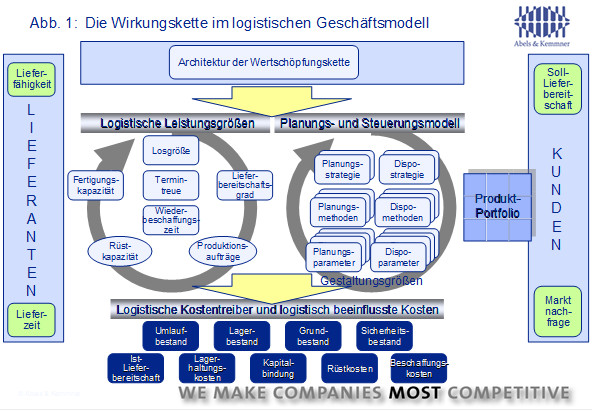

The logistical positioning can be achieved by adjusting the logistical performance indicators according to the requirements of the corporate business model and adapting the planning and control model. Fig.1 attempts to illustrate the abstract terminology and the chain of effects described:

The architecture of the value chain influences the logistics performance variables, such as batch sizes, replenishment times, capacity utilization, etc. These logistical performance variables are not only interrelated, but together with the planning and control model determine the level of logistical cost drivers and thus the total logistical costs. Fig. 1 illustrates this, in principle simple, connection.

Design parameters of the planning and control model include

- Planning and scheduling strategies,

- Planning and scheduling methods and parameters;

- Reported inventories;

- Covering periods

Central logistical cost drivers that are influenced are e.g:

- Basic stocks,

- Current stocks,

- Safety stocks,

- Actual delivery readiness levels

The resulting logistically induced costs can be,

- Storage costs,

- Order costs

- Capital commitment,

- variable set-up costs;

- variable procurement costs;

- etc.

The interrelationships described made it clear once again why new market potential and significant increases in efficiency can be achieved by not only concentrating on logistics positioning, but also by scrutinizing and adapting the architecture of the value chain and the logistics structure of the product portfolio, thus achieving a comprehensive Optimization of the logistics business model reached.

The extent of the interdependencies and the large number of adjusting screws make it difficult to achieve an optimized business model in a targeted and reliable manner. Traditional methodical project approaches, which rely heavily on the experience of the project team and simple static calculations, will only be able to achieve significant improvements, if at all, after a very long time and with many costly, sometimes even dangerous attempts.

A more effective and efficient way is to capture the described “overall system” with its interdependencies, make it calculable, identify the right control variables to optimize the overall system and set them appropriately.

We solve this problem, even with highly fluctuating demand structures and complex value chains, with the help of our DISKOVER SCO simulation system, which has been continuously developed and expanded for over 17 years. With the help of supply chain simulations, we are able to dynamically simulate the logistical behavior of the entire value chain. To do this, we draw data from the ERP system (ideally, but not necessarily SAP), which we use to build up the value stream in detail and dynamically run through it over time with the help of real, detailed historical data.

In this way, we can simulate different logistical structures with different logistical performance levels and different planning and control models and arrive at optimized solutions.

By simulating the entire logistics business model and determining logistics performance and logistics-influenced costs, we are able to,

- evaluate and optimize different alternative courses of action,

- to secure and accelerate decisions and

- shorten the time between concept and resulting benefits

Using the simulation approach, we are not only able to optimize a logistics business model or coordinate a corporate business model with a logistics business model. Sub-aspects can also be picked out and dealt with, such as

- Reduce inventories and capital commitment

- Improve delivery capability

- Simplify and automate the planning process

- Improve planning quality

- Tuning and automatically readjusting the ERP system

- Reduce personnel deployment in the planning and control chain.

Making the internal and external supply chain calculable is not only a more effective and efficient solution on balance, but practically the only way to assess the overall impact of simple or complex packages of measures in advance and thus avoid costly mistakes. The opportunity to work on 75% of the controllable value-added costs in the company is certainly worth the effort.

Further information:

How much safety stock does your company need?

How to get a handle on thousands of planning parameters