The ongoing adjustment of your own scheduling parameters is a recurring task that is criminally neglected by many. The correct setting of the parameters could still save costs of a significant order of magnitude. External service providers help with the fine-tuning of scheduling management.

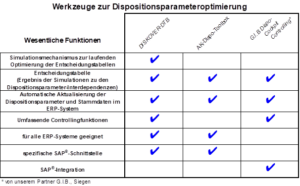

When it comes to taxes, no entrepreneur today doubts whether it makes sense to use an external specialist for strategic measures. The same should apply to inventory management, but it often does not, for one clear and simple reason: intensive communication between scheduling, sales, shipping and purchasing as well as customers and especially suppliers is necessary. This is why daily inventory management must also be integrated into the company in terms of time and location. However, the task of providing inventory management with optimized parameters is in many cases better handled externally (Fig. 1). There are many reasons for this.

Fine-tuning requires detailed expertise

In particular, the precise calculation of scheduling parameters requires highly detailed expertise, which is all too rarely available in the company. For example, the item-specific optimization of forecast parameters and any seasonal factors is a very complex task for which not every dispatcher is adequately prepared.

Ensure repeated updating

In addition, experience has shown that hardly any dispatchers have the time to repeatedly carry out item-specific optimizations for 20,000 or more items in their day-to-day business. As a result, the basic parameterization set when the system was introduced is only updated very rarely. Often only one procedure and the same parameter settings are used for all articles and no article-specific adjustments are made.

Software often still inadequate

Even if the time and know-how required to carry out the necessary calculations and permanent maintenance in the system are not the problem, many companies still have one problem: most ERP/PPS systems are unable to fulfill the tasks adequately. This is despite the fact that modern merchandise management systems, which are associated with high investments, cover company-wide functionalities. It is therefore no exception that such systems can still perform an ABC analysis (sales relevance), but fail due to the requirement for an XYZ analysis (consumption behavior). It also happens that automatic optimization runs are offered for the stock, but the readiness for delivery is sometimes neglected. The planning and forecasting procedures of most systems also require, for example, a normally distributed historical time series of the consumption behavior of the items. However, this condition only applies in 5 percent of all observed distributions, as a study by RWTH Aachen University has shown. According to this, as many as 25 percent of the distributions could not be assigned to any common distribution type at all.

Even if a distribution type is applicable, it is not determined in most companies anyway due to the high calculation intensity – with the result that the planning results are often only suboptimal. And although most systems offer fields for seasonal factors, these have to be maintained manually. Here, too, the question arises as to who can determine these factors – by calculation and not by feeling! -and who is supposed to do and maintain this for several thousand articles?

Articles must be checked regularly

The scheduling problem is also exacerbated by the fact that certain decisions have to be made repeatedly at fixed intervals. It should therefore be regularly checked whether the planning and scheduling procedures set for the individual items can still be used. An item that begins its life cycle as a CZ item (low sales relevance, sporadic demand) may develop further into a BY or even AX item (medium to high sales relevance, regular demand), falls off again, comes back to life and at some point becomes a CZ item again as its life cycle draws to a close.

However, AX articles must be planned and scheduled differently than CZ articles. Therefore, the current positioning of all articles should be permanently determined via the article structuring. As a result, the planning and scheduling procedures must be adapted accordingly.

The practical case of trading in car parts

Herth + Buss GmbH & Co. KG in Heusenstamm has dared to do the unthinkable and outsourced parts of its scheduling management to an external service provider. Herth + Buss distributes spare parts in the automotive and automotive electrics sector. The product range comprises a total of approx. 16,000 parts. An important competitive feature of customer order processing is that goods ordered by the customer by 4 p.m. are delivered by overnight express and are available to the customer the next day. This requires a high level of readiness to deliver the entire stock range.

The Herzogenrath-based management consultancy Abels & Kemmner has now been called in to optimize the core parameters of inventory management. The consultants first analyzed the relevant data over a period of almost two years at the end of each quarter. The parameters were then optimized and transferred to the system. Together with the company, the range of articles was divided into article classes and the best possible degrees of readiness for delivery were simulated and defined for the individual classes. With this target formulation, the aim was to minimize stocks and recalculate all parameters at the end of each quarter and transfer them back to the host system.

Within six months, the inventory range was reduced by around 25 percent and subsequently maintained. In the same period, the level of delivery readiness rose to 99%, leading to sales growth of around 10%.

The procedure with external consultants

Collaboration with external partners takes place in two steps (Fig. 2). The first step is to investigate and determine how and under what conditions the process and parameters can be optimized. In the second step, the analysis is repeated at intervals and is ultimately completed with the import of the results into the respective merchandise management system.

First, the relevant process data for order processing and the planning procedures available in the MRP system are determined. Data quality must be checked, as experience has shown that there are massive deficits in this area, which can greatly distort the results in the course of an analysis. Comprehensive discussions on data interpretation are particularly important. For example, what is actually entered in the “Requested delivery date” field? Is this the current date entered by the system or the delivery date actually requested by the customer? How should the “confirmed delivery date” be interpreted? Is it fixed or, as one company found out, is it adjusted and updated in the weekly net change, which of course results in a fantastic actual delivery readiness level, taking confirmed delivery dates into account?

It is also necessary to check how far back the available historical transaction data goes and in what form it can be provided, e.g. at document level or on a time basis, possibly cumulated over months. Finally, the data transfer must be defined. This includes which file and data record formats are used, via which medium and at what intervals the transfer takes place.

After all, you also have a tax advisor

Just as the tax consultant is often more familiar with the intricacies of tax law than the entrepreneur, the optimization of scheduling parameters by external service providers also leads to a significant increase in the efficiency of existing merchandise management. Abels & Kemmner determined from 34 consulting clients that 43 percent of the companies surveyed had a savings potential of between 20 and 25 percent, 32 percent were even able to save more than 25 percent. This shows that outsourcing scheduling optimization makes economic sense in many cases.