Inventory optimization at GAH Alberts

by Stefan Thomas 1, José Manuel Garcia Hidalgo 2 and Armin Klüttgen3

With suitable short-term measures that target the strongest stock drivers, large stock reduction effects can be achieved very quickly. However, to ensure that these quick wins do not fizzle out just as quickly, sustainable measures must also be taken in order to achieve optimally aligned portfolio structures on a permanent basis. GAH Alberts has managed to drastically reduce stocks, starting with short-term measures. Subsequently, an optimized planning and scheduling system developed in parallel led to permanently low inventories.

In order to further improve the performance of planning and scheduling, GAH Alberts launched a project in January 2009, the first step of which was to quickly reduce inventory. Only after this first “quick-win” step was the systematic and sustainable reduction in inventories implemented. The advantage of this strategy is that you can create liquidity quickly with quick wins and only then have to implement sustainability.

In order to further improve the performance of planning and scheduling, GAH Alberts launched a project in January 2009, the first step of which was to quickly reduce inventory. Only after this first “quick-win” step was the systematic and sustainable reduction in inventories implemented. The advantage of this strategy is that you can create liquidity quickly with quick wins and only then have to implement sustainability.

The term “quick-win” may sound a bit like starting the “stock mower”, setting the cutting height and then driving blindly over the crop. However, such actions are not intended, as they very quickly lead to a later “quick loss” after the first quick successes.

Completely changing the planning and replenishment strategy from one day to the next is also not a suitable quick-win strategy, as you cannot or should not turn such a large wheel without the right concepts and the development of suitable strategies.

Why quick wins are not enough

Truly meaningful measures to achieve quick wins are characterized by the fact that they essentially take place in the existing planning and logistical environment. They are not subject to rolling, recurring optimization and are therefore rather static actions with a one-off character. Nevertheless, the potential to be leveraged is identified systematically and in a well-structured manner, the steps to be taken are carefully worked out and the effects of the actions are regularly reviewed. The aim is to achieve economic success quickly.

Once quick wins have been achieved, it is crucial that the initial rapid successes are also supported by sustainable measures in order to have the optimum stock structure in the warehouse at all times, not just today. GAH Alberts has now also completed this transformation from a quick win to a permanent win and the results are now well above the targets set at the start of the project.

The quick-winmeasures

After a rough assessment of the processes, initial simulations and the implementation of inventory driver workshops, a package of measures was defined that should lead to a significant reduction in inventories in the short term. Indications from the portfolio driver workshops and the initial simulations were primarily used to identify the right measures.

The simulations showed which were the top 100 items with inventory reduction potential. These were then scrutinized in detail to determine the causes of the inventory, and in some cases they were converted or reduced by appropriate use. The following measures were also implemented:

- Introduction of zero parts (no consumption for at least twelve months) into a structured utilization or recycling process

- Reduction of reorder points with an MB envelope < x

- Reduction of safety stocks with a self-service envelope < x

- Reduction of batch sizes with an LG envelope < x, based on packaging units and where possible set to exact batch size

- Stop replenishment for items with stock range > Replenishment time *x and stock value > y €

- Correction of pre-plan values where the plan quality deviates significantly (average deviation plan vs. actual quantity)

- Check open orders for planning necessity, cancel or postpone if necessary

- Reduction of demand lead times in the system

- Allocation of monthly requirements to weekly requirements

The items identified according to the above criteria formed action lists that were handed over to the employees of the relevant departments, e.g. scheduling, sales or purchasing, for processing. In intensive workshops with the consulting firm Abels & Kemmner , a large number of articles were discussed directly in the ERP system and the further handling of the articles was determined.

The result of the efforts to achieve quick wins was that after around four months, inventories had already fallen by more than 13 percent, while delivery readiness had not diminished.

Permanent wins in an optimized planning environment

While the short-term measures continued to take effect, work had begun in parallel to secure the permanent win. A concept for optimizing planning and scheduling incl. The system-supported rolling adjustment of all relevant scheduling parameters was developed.

Where possible, the concept envisaged switching from the previous push strategy to a pull strategy for replenishment. Previously, preliminary plan values were entered into the system twice a year, which then had a dispositive effect.

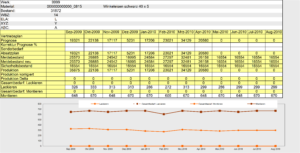

In future, a large proportion of the product range will be planned and scheduled based on consumption. However, as new planning is now carried out on a rolling monthly basis, it is of course also necessary to decide on a monthly basis which items are suitable for consumption control, which MRP type they should be assigned, how the relevant parameters, e.g. safety stock and reorder level, should be dimensioned for them and how the specified target delivery readiness level should be set.

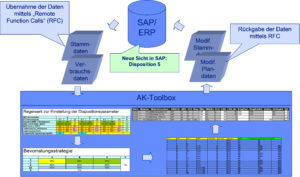

These decisions are taken by the planner from a set of rules, which is automatically processed by the AK-Toolbox (a tool from Abels & Kemmner) and makes the necessary changes in the SAP system after approval by the planner. The regulations take into account the following information, among others:

- ABC license plate

- XYZ license plate

- Life cycle indicator (ELAN)

- Material type

- Special stock keeping indicator

- Length of the consumption history

As events can occur at any time, not just at the end of the month when rolling planning is carried out, which can influence the demand for prefabrication and the reorder level, the sales staff are required to enter such information into the system on an event-driven basis and therefore promptly. Typical events in this area are promotions or new or lost customers with significantly high purchase volumes. In such cases, the sales department should make absolute and/or percentage corrections to the forecasts created by the system in the sense of exception planning. The corrections are then aggregated at item level and then processed further, as each sales employee performs this activity for their own trading partners.

The closed loop between AK-Toolbox and SAP, which runs every night, ensures that all special events in sales planning are immediately taken into account, whereby the statistical forecasts and relevant sales information are integrated into the effective sales plan (Fig. 2).

The rolling calculation of the reorder levels to be discontinued presents the particular challenge of having to take into account not only the strong seasonal business, but also the need for prefabrication due to limited capacities.

Determination of prefabrication requirements

If, like GAH Alberts, you have to prefabricate for the new season months in advance, then you face a very special problem: The time of sale is still a long way off, but you still have to decide which products to produce to full specification and put into stock.

In accordance with the trumpet effect, which states that the forecast for the distant future is affected by more uncertainty than that for the near future, the risk of producing the wrong materials or the wrong quantities is naturally also significantly higher. Failure to solve this problem jeopardizes the optimal inventory structure and the desired delivery readiness.

At GAH Alberts, the ABC/XYZ classification of items is used as a guide when deciding which items are preferable in which quantities in production. The basic idea is to give preference to regular items first, as there is less risk of them ending up as slow sellers. The sequence is from A to C and X to Y, i.e. AX parts first, followed by BX parts and so on. Only X and Y parts should be brought forward automatically, but not Z or Z2 parts, which have very sporadic consumption characteristics. If the bottleneck situation has not yet been resolved, a message should be issued and the planner must intervene manually.

A “pull-forward factor” is also used. This indicates how much of the quantity to be produced may be brought forward. This factor is article-specific and can also be used to ensure that certain articles are not prefabricated at all.

An article can run through several bottlenecks in succession. This means that one bottleneck with its prefabrication influences the other in turn in its capacity utilization situation. This situation must therefore be resolved iteratively for all bottlenecks.

Setting the optimum parameters

The corrected production situation is then used to determine corrected reorder levels so that planned prefabrication can also be implemented operationally for consumption-controlled items. For this purpose, the reorder levels are increased with a calculated lead time earlier than determined by the ERP system.

The result is that, contrary to the actual consumption situation, an increased reorder level triggers replenishment at an early stage.

In addition to other parameters, such as the MRP characteristic to be set, the reorder point is transferred to SAP, where it is then taken into account in day-to-day business. SAP can thus generate planned orders and purchase requisitions at any time on the basis of optimally set parameters, which deliver the right material at the right time and in the right quantity (Fig. 3).

Conclusion after nine months

The Gust. Alberts GmbH & Co. KG has succeeded in streamlining processes, reducing costs and at the same time achieving the specified delivery readiness. New strategies and processes have been established in planning and scheduling, supplemented by significantly enhanced system support to achieve the desired performance and planning quality.

Impressive results are achieved through the realization of quick wins and the rapid transition to permanent wins. After a 13% reduction in inventories in four months, inventories were down 53% after nine months. To be able to classify this performance correctly, you have to look back at the project objective, which was: 30 percent, half of it in the first twelve months.

Sustainable reduction in inventories despite seasonal business

In the GAH Alberts inventory optimization project, in which inventories were to be drastically reduced by 30 percent, two special features had to be taken into account: Firstly, there was a particular focus on the delivery readiness to be maintained, as the DIY stores, as customers of GAH Alberts, place very high demands on the delivery rate to be achieved. Secondly, GAH manufactures products that are subject to extremely strong seasonal fluctuations, as many materials are produced and sold for the garden sector, among other things. During the peak season, the available production capacities are not sufficient to fully synchronize production with the market. This means that the quantities you plan to sell sometimes have to be produced weeks or even months before the planned sales. The consequences of inaccurate sales planning are obvious: sales cannot be realized due to a lack of materials, and other materials remain in the warehouse as slow-moving items.

GAH Alberts

The history of Gust. Alberts GmbH £t Co KG as a bolt forge in the Sauerland region. Now in its fourth generation, the company is a successful global system provider for trade, craft and industry with over 6,000 trading partners throughout Europe.

Employees from 26 nations, embedded in four sales companies, international holdings and globally active cooperations as well as the production location in Europe and global procurement ensure the delivery readiness and high quality demanded by the market.

GAH Alberts offers a wide variety of products for home and garden as standardized products or as custom-made products in various categories (cf.

www.gah.de

).

1 Stefan Thomas – Head of Logistics at GAH in Herscheid

2JoséManuel Garcia Hidalgo – Head of Disposition Center at GAH in Herscheid

3ArminKlüttgen – Principal at Abels und Kemmner GmbH