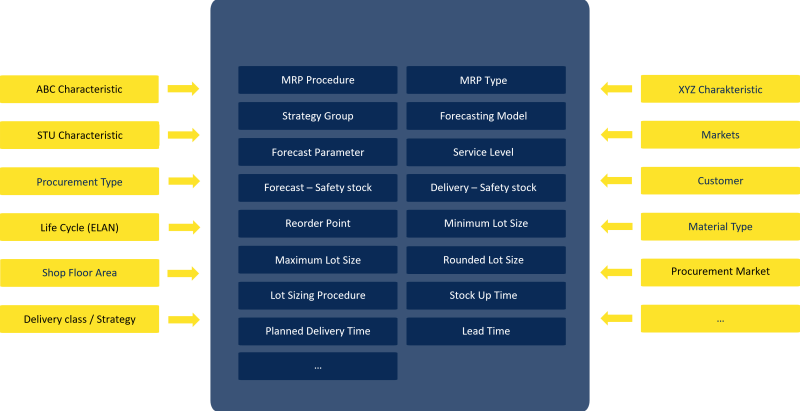

MRP parameters

Planning and scheduling master data must be continuously adapted and maintained to the changing boundary conditions of each article. If this does not happen, planning and scheduling results are inevitably wrong, work is done to the best of one’s knowledge and belief and delivery readiness and stocks become the random results of arbitrary decisions.

A simple calculation shows that an average planner would have to spend three to six months of their working time on maintaining planning and scheduling data alone.

Planners and schedulers usually do not have the time to set up planning and scheduling master data correctly and some of them also lack the necessary specialist knowledge of ERP algorithms.

Master data can be maintained automatically using modern tools. With our simulation approach, we help you to develop and implement the right economic rules for your planning and scheduling parameters.

What are MRP parameters and what do they depend on?

As supply chain experts, we see our individual services as building blocks that need to fit into the "big picture" in order to achieve the goal of an optimised supply chain.

Prof. Dr. Andreas Kemmner