Heijunka boards in the final assembly of writing instruments at Montblanc

Peter Hartwig, Carsten W. Hense, Andreas Gillessen, Dr. Andreas Kemmner1

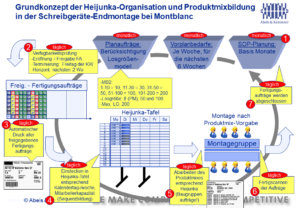

Montblanc-Simplo GmbH has further developed the Heijunka principle so that it not only serves to level the final assembly of the writing instruments, but also controls the multi-stage and multi-day assembly processes.

At its Hamburg site, Montblanc-Simplo GmbH handcrafts high-quality writing instruments from several different unlimited product lines such as Meisterstück, Bohème, Starwalker and Etoile in a wide variety of model designs. In addition, special limited-edition devices are produced in the manufactory in quantities ranging from a single unique piece to several thousand.

Kanban system across several control loop stages

For the past eight years, the deep-stage production of individual parts and components for the unlimited appliance models has been controlled using a hybrid Kanban system. In this Kanban organization, control takes place on site using Kanban cards and Kanban boards. The production progress is tracked via scanning processes in the SAP system. This Kanban control chain, which in some cases extends over several control loop stages, ends before final assembly in the so-called EMO warehouse, the supermarket for final assembly. This production organization of Montblanc’s individual part and component production has proven itself over the past eight years and has led to significantly lower inventories and work in progress as well as higher delivery reliability of the supermarket for final assembly.

SAP production orders for final assembly

Until the end of 2009, final assembly itself was controlled by traditional SAP production orders, which were triggered by the SAP system based on the monthly calculated target and reorder levels of the finished appliances. In this way, a continuous production process was realized right through to the market.

Final assembly was controlled for writing instruments with high sales and more regular market demand by means of target inventory control, which is the result of a differentiated monthly rolling sales planning and production program planning process. Reorder points are automatically calculated each month for writing instruments with lower sales and irregular demand. The result of the rolling monthly sales planning process is not only leveled annual seasonalities, target and reorder levels, but also re-dimensioned Kanban control loops for the production of components and individual parts.

Significant fluctuations in capacity utilization

However, fluctuations in demand and the resulting varying levels of replenishment requirements in the finished goods warehouse repeatedly led to noticeable fluctuations in capacity utilization in final assembly. In addition, the SAP system triggered production orders with relatively large batch sizes. Both effects together resulted in varying material withdrawal quantities per time unit from the final assembly supermarket, which in turn caused fluctuations in demand in the individual Kanban control loops. In the first years of Kanban control, these could still be absorbed by the Kanban control loops, as capacity reserves were available in almost all production areas. These reserves made it possible to increase production throughput at short notice and replenish the final assembly supermarket in good time.

Limited elasticity of the Kanban control cycles

However, the changing product portfolio of recent years has pushed production utilization ever closer to the limits of capacity, thus limiting the elasticity of the Kanban control loops. For these reasons, fluctuations in demand from final assembly increasingly led to supply bottlenecks. Due to fluctuating demand from the finished goods warehouse on the one hand and poorer supply reliability from the Kanban supermarket on the other, the final assembly of writing instruments was facing a production bottleneck.

Goals of the Heijunka organization

A Heijunka control system was introduced in final assembly at the beginning of 2010 in order to smooth and stabilize capacity utilization in final assembly and thus reduce fluctuations in demand in the production areas and Kanban control loops.

The term Heijunka refers to the process of smoothing out the necessary capacity requirements in conjunction with a higher product mix of the parts to be manufactured in the individual assembly lines in order to bring as much calm as possible to production within given capacity limits without losing the focus on demand. The specific objectives of the Heijunka control system at Montblanc were:

- increase the product mix in the individual assembly lines,

- reduce the fluctuations in capacity requirements in the individual assembly lines,

- to create transparency for the utilization and capacity requirement situation in the individual assembly lines,

- reduce the number of missing parts when removing components from the final assembly supermarket,

- to stabilize the parts and components tapped from the final assembly supermarket and thus stabilize the Kanban control loops across the various production stages,

- reduce work in progress in final assembly,

- create the prerequisites for reducing work in progress in the Kanban control cycles and

- to develop an instrument for operational self-control of the assembly groups.

Simple principle for complex processes

The special feature of Heijunka processes, such as final assembly at Montblanc, is that not just a single production step or a short assembly sequence consisting of several small steps is controlled. Instead, a multi-stage assembly process is controlled, in which the production of a final device can be spread over up to a week due to drying times after gluing work steps. In order to still be able to map the assembly process efficiently in an easy-to-handle Heijunka process, a number of conceptual, technical and organizational challenges had to be overcome.

Phase 1: Provision of the Heijunka orders

The sales planning process is used to generate monthly pre-planning requirements at weekly level for the next six weeks. To cover the planned requirements, the SAP system generates planned orders according to a defined batch size model with production order quantities between 10 units and a maximum of 200 units for the fastest-moving end devices. In the daily MRP run, the SAP system generates Heijunka orders with an opening horizon of two weeks. Based on an automatic availability check, only fully part-covered production orders are opened, released and printed out on a special card printer.

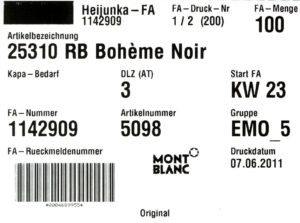

An order has several cards

A Heijunka order consists of several cards. It contains a Heijunka production order card and several assembly cards. The following essential information is noted on a Heijunka production order: material name and material number, the production order number and a barcode with the production order confirmation number, the production quantity, the calendar week in which the production order must be started, the planned lead time in working days until completion of the production order and the capacity requirement of employees for the entire production order.

Precisely recorded assembly times

All assembly times were re-recorded and coordinated with final assembly in order to be able to precisely determine the required capacity for the Heijunka orders. Distribution and waiting times are already taken into account in the capacity requirements. The capacity requirement stated on a Heijunka production order always refers to the working time per day of a full-time employee.

Each Heijunka order contains one assembly card for each assembly stage (assembly). A typical Heijunka order for a fountain pen, for example, contains five cards for the front part, container, cap, cone and completion assemblies.

Phase 2: Heijunkaboard assembly

The production logistician sorts the printed Heijunka production orders into the Heijunka board. The Heijunka board consists of four sections:

- Orders in arrears (weekly grid division)

- Orders for the current calendar week (in a daily grid)

- Orders for the next calendar week (in a daily grid)

- Orders for later calendar weeks (in a weekly grid)

The vertical scale of the Heijunka board shows the capacity requirements of a day or a week in terms of the number of employees.

Each Heijunka production order is placed on the board according to the calendar week noted on it. An assignment to a weekday is also made for the current and next calendar week. Within the weekday, the Heijunka production orders are categorized according to their capacity requirements, measured in employees. Each day or week is filled up to the maximum employee capacity of the weekday or calendar week, whereby the maximum employee capacity per day is specified by the head of final assembly. If the employee capacity is not sufficient or if there is a capacity surplus, an agreement is reached with the assembly management on ways to compensate for this.

>

The Heijunka boards are rebuilt every Friday afternoon. Heijunka production orders for the current week that have not yet been processed are moved to the “Backlogged orders” section of the Heijunka board. The Heijunka production orders of the next week become orders of the current week and the next week is built up with new Heijunka production orders.

Based on the pending Heijunka production orders, the assembly cards are now sorted into the “assembly order box” by the group leader.

High-quality writing instruments are complex instruments that consist of several assemblies. A fountain pen is usually made up of five such groups. For many assemblies, not only mechanical pre-assembly takes place, but bonding processes must also be carried out, with each bonding step requiring a drying process lasting 24 hours. The assembly process for a writing instrument can therefore take three to five working days. The assembly order box is divided into weekdays accordingly. The assembly cards of each Heijunka order are now sorted into the box with the corresponding time offset between the assemblies so that all Heijunka production orders and therefore all assembly cards will have been processed by the end of the working week, provided no faults occur.

Phase 3: Assembly control using assembly cards

Work distribution within the group, material provision from the final assembly supermarket and assembly progress tracking over the working week are carried out with the help of the assembly cards. The employees in an assembly group remove the cards from the order box independently. Each module card lists all the components required for module assembly. The required individual parts can be taken from the final assembly supermarket using the parts lists. The majority of the individual parts required are located directly at the work area of the assembly group. Only special parts and high-quality components are stored separately for safety reasons. Once the assembly lot of an assembly group has been fully assembled, it is placed in a buffer area until it is assembled again in the next work step, possibly after a drying time. If the scope of work of an assembly card is fulfilled, the card remains on the assembly.

If the assembly group still has backlogged Heijunka orders from the previous week to process, these are processed with first priority at the beginning of the week. In order to be able to cope with this and at the same time not fall behind with the current week, the employee capacity may have to be increased by the management of final assembly.

Phase 4: Completion notification

Once an assembly order has been completely processed, the corresponding Heijunka production order card is taken from the Heijunka board and “scanned” in the SAP system. The finished assembly lots are forwarded to the finished goods warehouse with the Heijunka papers.

For those in a hurry: an overview of the four phases of the process

- Phase: Replenishment requirements for the finished goods warehouse in the SAP system are broken down into smaller assembly lots and printed out as Heijunka orders for the individual assembly groups.

- Phase: The production logistics manager or the group spokesperson of an assembly group provides a Heijunka board with the printed Heijunka cards, the required personnel capacities in the various assembly groups are compared and the so-called assembly order box (see below) is filled.

- Phase: The multi-stage assembly of the devices, according to the specifications in the assembly order box.

- Phase: Completion of the order by scanning the Heijunka production order card, the so-called “final scan”.

The result

The Heijunka organization in final assembly has proven itself at Montblanc for over two years now and has developed into a key design element of Montblanc’s lean strategy.

Originally developed with a pilot group, the organizational principle has since been successfully extended to all assembly teams. The result: the assembly teams now work in a more relaxed and yet more efficient manner; friction losses and hectic due to missing components and/or order backlogs no longer occur. Even if parts are missing for a short time despite availability checks, this does not disrupt the assembly teams’ workflow: they can intervene independently and bring forward other assembly orders as part of the weekly planning – even an order from the following week if necessary. The planning of personnel requirements has also been significantly simplified and safety stocks in the Kanban control loops in production have been reduced thanks to the more consistent removal of components. In final assembly, too, work in progress has decreased as orders can now flow through assembly more quickly.

The result shows that demand orientation does not necessarily mean hectic and inefficiency, because with Heijunka it is possible to produce very efficiently in line with the market even with given capacity limits.

Further information on this topic can be found here:

- Digital bottleneck management at Montblanc

- Case study: Kanban at Chiron

- Kanban: Correctly calculate, reliably design and successfully implement replenishment according to the supermarket principle

- Logistical process analysis