With Disposition 4.0 to Industry 4.0

Industry 4.0 is currently on the minds of practically all companies. In my conversations with many managers, I regularly sense the worry of missing out on jumping on a speeding express train. However, many companies do not know where and when the train will pass by and where it will go. A quick glance at the press and the internet is of little help; the many buzzwords are rather frightening and no concrete steps to take are mentioned. Unfortunately, Industry 4.0 was quickly hijacked by the sensor and control system providers, and many believe that only upgrading machines, tools, devices and parts with sensors in order to automate production processes will lead to the digital factory. In reality, the store floor is just one building site in the development plan for Industry 4.0 and probably the one that will take the longest and cost the most, but will not offer the greatest potential by far.

Industry 4.0 is first and foremost about flexibly automating processes and workflows, making consistent use of today’s information technology possibilities and, if necessary, using them as a basis for further development. to derive new business models. For this reason, there is no standard action plan for the digitalization of the value chain, whether in retail or industry, but only individual, company-specific paths. Everyone has to find their own approach and none of the paths have to be wrong.

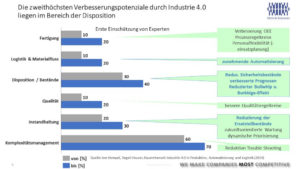

Now that the dust that has been stirred up on the store floor by Industry 4.0 has settled somewhat, it is becoming apparent that there are a whole range of opportunities to drive digitalization beyond the store floor. Starting points that offer significantly greater potential with considerably less effort and in a considerably shorter time. A survey of experts[1] provides interesting information in this regard, showing that after reducing complexity, the greatest potential of Industry 4.0 lies in the area of scheduling. In our experience, there is also considerable potential for automation and optimization here.

We have compiled some information for you at www.Disposition40.de.

[1] Thomas Bauernhansl, Michael ten Hompel, Birgit Vogel-Heuser (ed.):

Industry 4.0 in production, automation and logistics: application – technologies – migration; Springer-Verlag, Wiesbaden, 2014